Okwu mmalite

Dịka ahụ ụgbọ ala bụ onye na-ebu akụkụ ndị ọzọ nke ụgbọ ala ahụ, teknụzụ nrụpụta ya na-ekpebi ụdị nrụpụta ụgbọ ala n'ozuzu ya.Ịgbado ọkụ bụ usoro mmepụta ihe dị mkpa na usoro nke imepụta ahụ ụgbọ ala.Ka ọ dị ugbu a, teknụzụ ịgbado ọkụ a na-eji maka ịgbado ọkụ nke anụ ahụ gụnyere gụnyere ịgbado ọkụ ntụpọ, MIG ịgbado ọkụ, ịgbado ọkụ MAG na ịgbado ọkụ laser.

Teknụzụ ịgbado ọkụ laser dị ka teknụzụ ịgbado ọkụ optoelectromechanical dị elu, ma e jiri ya tụnyere teknụzụ ịgbado ọkụ anụ ahụ nke ụgbọ ala ọdịnala, nwere uru nke njupụta ume dị elu, ọsọ ịgbado ọkụ ngwa ngwa, nrụgide ịgbado ọkụ obere na nrụrụ, yana ezigbo mgbanwe.

Ọdịdị nke ahụ ụgbọ ala dị mgbagwoju anya, ihe ndị mejupụtara ya na-abụkarị ndị nwere mgbidi ma gbagọọ agbagọ.A na-enwe ụfọdụ ihe isi ike ihu igwe ịgbado ọkụ n'ahụ, dị ka mgbanwe n'ihe anụ ahụ, ọkpụkpụ dị iche iche nke akụkụ ahụ, ọnọdụ ịgbado ọkụ dị iche iche na ụdị nkwonkwo.Na mgbakwunye, ịgbado ọkụ ahụ ụgbọ ala nwere nnukwu ihe achọrọ maka ịdị mma ịgbado ọkụ yana arụmọrụ ịgbado ọkụ.

Dabere na ihe kwesịrị ekwesị ịgbado ọkụ usoro parameters, laser ịgbado ọkụ nwere ike hụ na elu ike ọgwụgwụ ike na mmetụta siri ike nke isi components nke ụgbọ ala ahụ, ka iji hụ na ịgbado ọkụ àgwà na ọrụ ndụ nke ụgbọ ala ahụ.Teknụzụ ịgbado ọkụ laser nwere ike imeghari ụdị nkwonkwo dị iche iche, nha dị iche iche na ụdị ihe dị iche iche nke akụkụ ahụ nke ịgbado ọkụ, iji gboo mkpa mgbanwe nke imepụta ahụ.Ya mere, teknụzụ ịgbado ọkụ laser bụ ụzọ teknụzụ dị mkpa iji nweta mmepe dị elu nke ụlọ ọrụ ụgbọ ala.

Teknụzụ ịgbado ọkụ laser nke ahụ ụgbọ ala

Laser miri penetration ịgbado ọkụ technology nke ụgbọala ahu

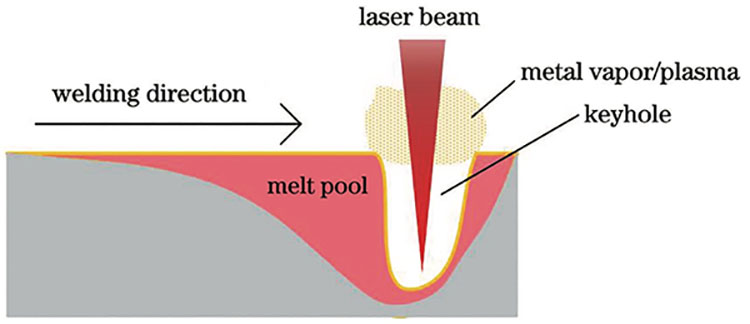

Ụkpụrụ nke usoro ịgbado ọkụ miri emi nke laser (Onyonyo 1) bụ ndị a: mgbe njupụta ike laser ruru otu ọkwa, elu nke ihe ahụ na-ekpu, na-akpụ isi.Mgbe igwe ikuku ikuku dị na oghere ahụ ruru nguzo siri ike na nrụgide static na nhụsianya elu nke mmiri mmiri gbara ya gburugburu, laser nwere ike ịgbatị ya na ala nke oghere ahụ site na oghere igodo, yana site na mmegharị nke eriri laser, na-aga n'ihu. weld e guzobere.N'oge laser miri penetration ịgbado ọkụ usoro, ọ dịghị mkpa ka ịgbakwunye inyeaka flux ma ọ bụ filler, na workpiece onwe ihe nwere ike welded ọnụ.

FIG.1 Schematic eserese nke laser miri penetration ịgbado ọkụ usoro

Weld nwetara site laser miri penetration ịgbado ọkụ na-adịkarị ire ụtọ na ogologo, na nrụrụ dị obere, nke na-enyere aka melite n'ichepụta ziri ezi nke ụgbọ ala.Ike dị elu nke weld na-eme ka ọ dị mma ịgbado ọkụ nke ahụ ụgbọ ala.Ọsọ ịgbado ọkụ dị ngwa ngwa, nke na-enyere aka melite nrụpụta nrụpụta ịgbado ọkụ.

Na usoro nke ụgbọala ahu ịgbado ọkụ, ojiji nke laser miri penetration ịgbado ọkụ usoro nwere ike ukwuu ibelata ọnụ ọgụgụ nke akụkụ, ebu na ịgbado ọkụ ngwaọrụ, si otú ibelata ahu arọ na mmepụta ihe.Otú ọ dị, usoro ịgbado ọkụ laser miri emi na-adịghị mma maka oghere mgbakọ nke akụkụ welded, yana mkpa ka a na-achịkwa oghere n'etiti 0.05 na 2 mm.Ọ bụrụ na oghere mgbakọ ahụ buru ibu, ntụpọ ịgbado ọkụ dị ka pores ga-eme.

The ugbu nnyocha na-egosi na weld na ezi elu-akpụ, obere esịtidem ntụpọ na magburu onwe n'ibu Njirimara nwere ike nweta site optimizing usoro parameters nke laser miri penetration ịgbado ọkụ na ịgbado ọkụ nke otu ihe nke ụgbọala ahu.The magburu onwe n'ibu Njirimara nke weld nwere ike izute mkpa nke ịgbado ọkụ akụrụngwa nke ụgbọala ahu.Agbanyeghị, na ịgbado ọkụ ahụ ụgbọ ala, teknụzụ ịgbado ọkụ laser miri nke metal laser nke aluminom alloy na ígwè nọchiri anya ya etobeghị.Ọ bụ ezie na ịgbado ọkụ seams na magburu onwe arụmọrụ nwere ike nweta site na-agbakwụnye mgbanwe n'ígwé, mmetụta usoro nke dị iche iche mgbanwe oyi akwa oyi akwa IMC na ha edinam usoro on weld microstructure bụ doro anya, na n'ihu nnyocha dị mkpa.

Ụgbọ ala ahụ laser waya na-ejuputa usoro ịgbado ọkụ

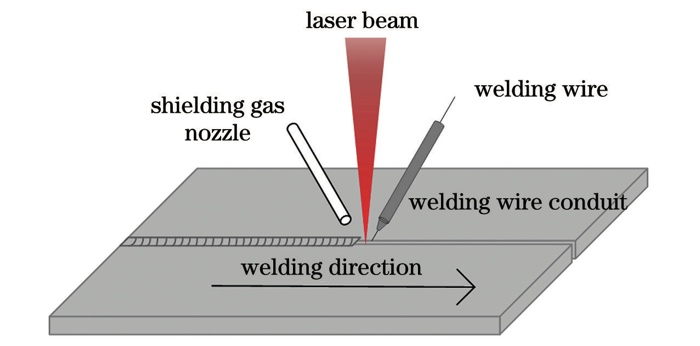

Ụkpụrụ nke usoro ịgbado ọkụ nke laser filler waya bụ nke a: a na-emepụta nkwonkwo welded site na-ejuputa otu waya ịgbado ọkụ n'ime weld ma ọ bụ na-eri nri ịgbado ọkụ n'otu oge n'oge usoro ịgbado ọkụ laser.Nke a dakọtara na ntinye ihe dị ka otu ihe ịgbado ọkụ n'ime ọdọ mmiri weld n'oge ịgbado ọkụ laser miri emi.E gosipụtara eserese schematic nke usoro ịgbado ọkụ laser filler waya na eserese 2.

FIG.2 Eserese eserese nke usoro ịgbado ọkụ laser waya

E jiri ya tụnyere laser miri penetration ịgbado ọkụ, laser waya ndochi ịgbado ọkụ nwere abụọ uru na auto body ịgbado ọkụ: mbụ, ọ nwere ike dị ukwuu mma ndidi nke mgbakọ ọdịiche n'etiti akpaaka ahu akụkụ na-welded, na-edozi nsogbu na laser miri penetration ịgbado ọkụ. na-achọ oke oghere nke ukwuu;Nke abụọ, a pụrụ imeziwanye nkesa anụ ahụ nke mpaghara weld site na iji wires ịgbado ọkụ nwere ihe dị iche iche mejupụtara, na mgbe ahụ enwere ike ịhazi ọrụ weld.

N'ime usoro nke imepụta ahụ ụgbọ ala, a na-eji usoro ịgbado ọkụ laser waya maka ịgbado ọkụ aluminom na akụkụ ahụ nchara.Karịsịa na usoro ịgbado ọkụ nke aluminum alloy akụkụ nke ụgbọ ala ahụ, elu erughị ala nke a wụrụ awụ ọdọ mmiri bụ obere, nke dị mfe iduga ọdịda nke wụrụ awụ ọdọ mmiri, na laser waya ndochi ịgbado ọkụ usoro nwere ike mma dozie nsogbu nke wụrụ awụ ọdọ mmiri ida. site n'ịgbaze waya ịgbado ọkụ.

Laser brazing teknụzụ nke ahụ ụgbọ ala

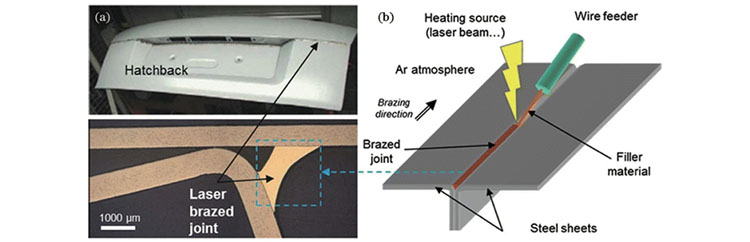

Ụkpụrụ nke usoro brazing laser bụ nke a: a na-eji laser mee ihe dị ka isi iyi ọkụ, ọkụ laser na-enwu n'elu waya ịgbado ọkụ mgbe a na-elekwasị anya, eriri ịgbado ọkụ na-agbaze, eriri agbaze na-adaba ma jupụta n'etiti eriri. akụkụ a ga-welded, na metallurgical mmetụta dị ka agbaze na mgbasa ime n'etiti filler metal na workpiece, nke mere na workpiece jikọọ.N'adịghị ka usoro ịgbado ọkụ nke waya laser, usoro brazing laser na-agbaze waya na anaghị agbazekwa workpiece ka a ga-agbaze.Laser brazing nwere ezigbo ịgbado ọkụ kwụsie ike, ma ike tensile nke weld dị ala.FIG.3 na-egosi ngwa nke usoro brazing laser na mkpuchi mkpuchi mkpuchi ụgbọ ala.

FIG.3 Ngwa nke brazing laser n'ime ụgbọ ala: (a) ịgbado ọkụ laser nke mkpuchi azụ;(b) Eserese eserese nke laser brazing

Na usoro nke ụgbọala ahụ ịgbado ọkụ, laser brazing usoro bụ tumadi ịgbado ọkụ akụkụ ahụ na ala nkwonkwo ike chọrọ, dị ka ịgbado ọkụ n'etiti elu cover na akụkụ mgbidi nke ahu, ịgbado ọkụ n'etiti elu na ala akụkụ nke ogwe osisi. mkpuchi, wdg, Volkswagen, Audi na ụdị ndị ọzọ dị elu nke mkpuchi elu na-eji usoro brazing laser.

The isi ntụpọ na laser brazing ịgbado ọkụ onuete nke ụgbọ ala ahu na-agụnye ọnụ ata n'ahụ, porosity, weld deformation, wdg The ntụpọ nwere ike kwụsị doro anya site n'ịgbanwe usoro parameters na iji multi-elekwasị anya laser brazing usoro.

Laser arc mejupụtara teknụzụ ịgbado ọkụ nke ahụ ụgbọ ala

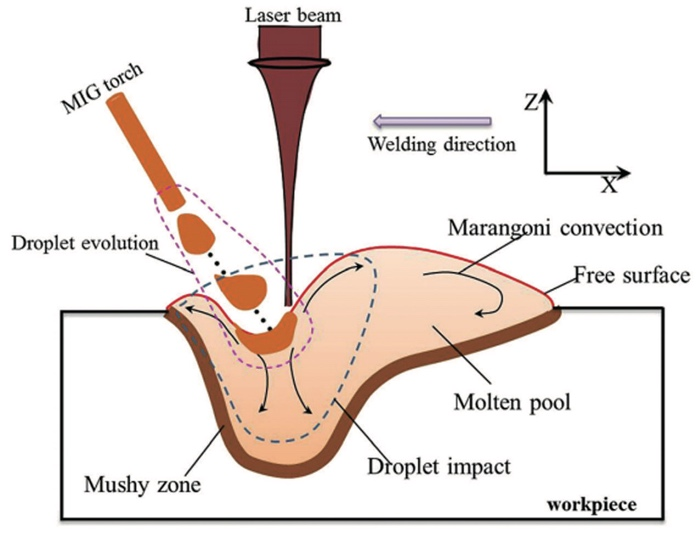

Ụkpụrụ nke usoro ịgbado ọkụ laser-arc mejupụtara bụ nke a: iji ọkụ ọkụ abụọ nke laser na arc na-eme ihe n'elu ihe a na-eme ka ọ bụrụ nke a ga-agbaze n'otu oge ahụ, a na-agbaze workpiece ma sie ike iji mepụta weld.Ọgụgụ 4 na-egosi schematic eserese nke laser-arc mejupụtara usoro ịgbado ọkụ.

FIG.4 Schematic eserese nke laser-arc mejupụtara usoro ịgbado ọkụ

Laser-arc composite welding nwere uru nke ma laser ịgbado ọkụ na arc ịgbado ọkụ: mbụ, n'okpuru omume nke okpukpu abụọ okpomọkụ isi mmalite, na ịgbado ọkụ ọsọ na-mma, okpomọkụ ntinye bụ obere, weld deformation bụ obere, na àgwà nke laser ịgbado ọkụ. a na-echekwa;Nke abuo, o nwere ikike ijikota nke oma na nnabata ka ukwuu nke oghere nzuko;Nke atọ, ọnụ ọgụgụ siri ike nke ọdọ mmiri a wụrụ awụ na-adị nwayọọ, nke na-eme ka ikpochapụ ntụpọ ịgbado ọkụ dị ka pores na cracks, na imeziwanye nhazi na arụmọrụ nke mpaghara okpomọkụ emetụtara.Nke anọ, n'ihi mmetụta nke arc, ọ nwere ike weld ihe na elu reflectivity na elu thermal conductivity, na nso nke ngwa ngwa bụ wider.

Na usoro nke ụgbọala ahu n'ichepụta, na laser-arc mejupụtara ịgbado ọkụ usoro bụ tumadi ka weld aluminum alloy components nke ahu na aluminum-steel dissimilar ọla, na ịgbado ọkụ na-rụrụ akụkụ na nnukwu mgbakọ gaps, dị ka ịgbado ọkụ nke akụkụ nke akụkụ. ọnụ ụzọ ụgbọ ala, n'ihi na oghere mgbakọ na-eme ka egwu egwu nke akwa akwa nke laser-arc composite welding.Tụkwasị na nke ahụ, a na-etinyekwa teknụzụ ịgbado ọkụ laser-MIG arc n'akụkụ oke ọkụ nke ahụ Audi.

N'ime usoro ịgbado ọkụ nke anụ ahụ ụgbọ ala, ịgbado ọkụ laser-arc mejupụtara nwere uru nke nnabata dị ukwuu karịa ịgbado ọkụ otu laser, mana ọnọdụ nke laser na arc, paramita ịgbado ọkụ laser, paramita arc na ihe ndị ọzọ kwesịrị ịtụle nke ọma.The okpomọkụ na uka nnyefe omume na laser-arc ịgbado ọkụ bụ mgbagwoju, karịsịa usoro nke ike regulation na IMC ọkpụrụkpụ na Ọdịdị ụkpụrụ na dissimilar ihe ịgbado ọkụ ka edoghị, na n'ihu nnyocha dị mkpa.

Ndị ọzọ akpakanamde ahu laser ịgbado ọkụ Filiks

Mgbado ọkụ laser miri emi, ịgbado ọkụ waya laser, brazing laser na laser-arc composite welding na usoro ịgbado ọkụ ndị ọzọ abụwo tiori tozuru oke na ngwa bara uru.Site na nkwalite nke ụlọ ọrụ ụgbọ ala chọrọ maka ịrụ ọrụ nke ịgbado ọkụ ahụ yana mmụba nke ọchịchọ maka ịgbado ọkụ dị iche iche n'ichepụta ụgbọ ala dị arọ, ịgbado ọkụ laser, ịgbado ọkụ laser, ịgbado ọkụ multi-laser beam na ịgbado ọkụ ụgbọ elu laser ka etinyere nlebara anya. ka.

Usoro ịgbado ọkụ laser ntụpọ

Laser ntụpọ ịgbado ọkụ bụ ihe elu laser ịgbado ọkụ technology, nke nwere uru nke ngwa ngwa ịgbado ọkụ ọsọ na elu ịgbado ọkụ nkenke.Ụkpụrụ bụ isi nke ịgbado ọkụ laser bụ ilekwasị anya n'ọkụ laser ruo n'ókè ụfọdụ na akụkụ a ga-agbaze, nke mere na ígwè dị n'ebe ahụ na-agbaze ozugbo, site n'ịgbanwe njupụta laser iji nweta ịgbado ọkụ ọkụ ma ọ bụ mmetụta ịgbado ọkụ miri emi. , mgbe eriri laser kwụsịrị ime ihe, igwe mmiri mmiri na-agbagharị, gbasiri ike na-etolite njikọ.

E nwere isi ihe abụọ dị iche iche nke laser ntụpọ ịgbado ọkụ: pulsed laser ntụpọ ịgbado ọkụ na-aga n'ihu laser ntụpọ ịgbado ọkụ.Pulsed laser spot welding laser beam peak ume dị elu, mana oge ime ihe dị mkpụmkpụ, a na-ejikarị eme ihe maka magnesium alloy, aluminum alloy na ịgbado ọkụ ọla ndị ọzọ.The nkezi ike nke laser doo na-aga n'ihu laser ntụpọ ịgbado ọkụ dị elu, laser edinam oge bụ ogologo, na ọ na-ọtụtụ ebe na-eji ígwè ịgbado ọkụ.

N'ihe banyere ụgbọala ahu ịgbado ọkụ, tụnyere na-eguzogide ntụpọ ịgbado ọkụ, laser ntụpọ ịgbado ọkụ nwere uru nke na-abụghị kọntaktị, ntụpọ ịgbado ọkụ trajectory nwere ike e mere onwe ya, wdg, nke nwere ike izute chọrọ nke elu-edu ịgbado ọkụ n'okpuru dị iche iche n'apata gaps nke. akụrụngwa ahụ ụgbọ ala.

Usoro ịgbado ọkụ laser

Ịgbado ọkụ nke laser bụ teknụzụ ịgbado ọkụ laser ọhụrụ a tụrụ aro n'afọ ndị na-adịbeghị anya, nke a na-enwekarị nchegbu.Ụkpụrụ nke nkà na ụzụ a bụ: site na ijikọta otu galvanometer na isi ịgbado ọkụ laser, ọkụ ọkụ laser na-adị ngwa ngwa, n'usoro na obere obere, iji nweta mmetụta nke eriri laser na-aga n'ihu mgbe ọ na-akpali.

Ụzọ mgbagharị isi na usoro ịgbado ọkụ laser na-agụnye ịgbagharị transverse, swing longitudinal, ịmagharị okirikiri na enweghị ngwụcha.Usoro ịgbado ọkụ laser nwere nnukwu uru na ịgbado ọkụ nke ahụ ụgbọ ala.N'okpuru ọrụ nke laser beam swing, ọnọdụ nke ọdọ mmiri a wụrụ awụ na-agbanwe nke ukwuu.Ya mere, usoro ahụ nwere ike ọ bụghị naanị iwepụ ntụpọ na-enweghị isi, nweta nhazi ọka ma gbochie porosity na ịgbado ọkụ nke otu ihe ahụ ụgbọala.Na mgbakwunye, ọ nwekwara ike melite nsogbu ndị dị ka ezughi oke agwakọta dị iche iche ihe na ogbenye n'ibu Njirimara nke welds na ịgbado ọkụ nke heterogeneous ihe nke ụgbọala ahu.

Multi-Laser doo usoro ịgbado ọkụ

Ka ọ dị ugbu a, enwere ike kewaa laser fiber optics n'ọtụtụ ebe ọkụ laser site na modul splitter etinyere na isi ịgbado ọkụ.Multi-Laser beam welding bụ ihe kwekọrọ na itinye ọtụtụ isi mmalite okpomọkụ na usoro ịgbado ọkụ, site n'ịgbanwe ike nkesa nke ọkụ ahụ, ogwe dị iche iche nwere ike ịrụ ọrụ dị iche iche, dị ka: ogwe nwere ike dị elu bụ isi ọkụ, na-ahụ maka miri emi. ntinye ịgbado ọkụ;Ngwunye ike dị ala nke osisi ahụ nwere ike ihicha ma kpoo elu nke ihe ahụ, na-amụba absorption nke ike ọkụ laser site na ihe ahụ.

Galvanized elu-ike ígwè ihe na-ọtụtụ ebe na ụgbọala ahu.Nkà na ụzụ ịgbado ọkụ nke ọtụtụ laser nwere ike imeziwanye omume evaporation nke zinc vepor na omume siri ike nke ọdọ mmiri a wụrụ awụ na usoro ịgbado ọkụ nke efere igwe galvanized, kwalite nsogbu sputtering, ma welie ike ike nke weld.

Usoro ịgbado ọkụ nke ụgbọ elu laser

Teknụzụ ịgbado ọkụ ụgbọ elu laser bụ teknụzụ ịgbado ọkụ laser ọhụrụ, nke nwere arụmọrụ ịgbado ọkụ dị elu yana enwere ike imepụta ya n'onwe ya.Ụkpụrụ bụ isi nke ịgbado ọkụ ụgbọ elu laser bụ na mgbe ọkụ laser na-eme na enyo X na Y nke enyo nyocha, a na-achịkwa akụkụ nke mirror site na mmemme nke onwe ya iji nweta ngbanwe nke eriri laser n'akụkụ ọ bụla.

Mgbado ọkụ laser ọdịnala nke ahụ ụgbọ ala na-adabere na mmegharị mmekọrịta nke isi ịgbado ọkụ laser na-ebugharị site na ịgbado ọkụ robot iji nweta mmetụta ịgbado ọkụ.Agbanyeghị, arụ ọrụ ịgbado ọkụ nke ahụ ụgbọ ala na-amachi nke ukwuu site na mmegharị robọt ịgbado ọkụ ugboro ugboro n'ihi ọnụ ọgụgụ dị ukwuu nke weld na ogologo welds.N'ụzọ dị iche, ịgbado ọkụ ụgbọ elu laser kwesịrị ịhazigharị akụkụ nke enyo iji nweta ịgbado ọkụ n'ime mpaghara ụfọdụ.Ya mere, teknụzụ ịgbado ọkụ ụgbọ elu laser nwere ike melite arụmọrụ ịgbado ọkụ ma nwee atụmanya ngwa ngwa.

Nchịkọta na atụmanya

Site na mmepe nke ụlọ ọrụ ụgbọ ala, teknụzụ ịgbado ọkụ anụ ahụ ga-aga n'ihu na-etolite n'akụkụ abụọ: usoro ịgbado ọkụ na teknụzụ nwere ọgụgụ isi.

Ahụ ụgbọ ala, ọkachasị ahụ ụgbọ ala ume ọhụrụ, na-etolite n'ụzọ nke dị fechaa.Lightweight alloys, mejupụtara ihe na dissimilar ihe ga-ọzọ n'ọtụtụ ebe na-eji na ụgbọala ahu, ot Laser ịgbado ọkụ usoro siri ike izute ya ịgbado ọkụ chọrọ, otú elu-edu na ịrụ ọrụ nke ọma ịgbado ọkụ usoro ga-aghọ ọdịnihu mmepe na-emekarị.

N'ime afọ ndị na-adịbeghị anya, usoro ịgbado ọkụ laser na-apụta, dị ka ịgbado ọkụ laser, ịgbado ọkụ ọtụtụ laser, ịgbado ọkụ ụgbọ elu laser, wdg, bụ nyocha usoro izizi na nyocha usoro n'ihe gbasara ịdị mma ịgbado ọkụ na arụmọrụ ịgbado ọkụ.N'ọdịnihu, ọ dị mkpa ijikọ nke ọma na-ejikọta usoro ịgbado ọkụ laser na-apụta na ihe dị arọ na ihe ndị dị iche iche na-agbado agbado nke ahụ ụgbọ ala, na-eme nnyocha miri emi na imewe nke laser beam swing trajectory, usoro ihe omume nke multi-laser beam energy. na mmelite nke ịrụ ọrụ ịgbado ọkụ ụgbọ elu, wee chọpụta usoro ịgbado ọkụ n'ahụ ụgbọ ala tozuru oke.

Teknụzụ ịgbado ọkụ laser nke ahụ ụgbọ ala jikọtara ya na teknụzụ nwere ọgụgụ isi.The ezigbo oge nghọta nke laser ịgbado ọkụ steeti ụgbọala ahu na nzaghachi akara nke usoro parameters egwu a bụrụkwa ọrụ na ịgbado ọkụ àgwà.A na-ejikarị teknụzụ ịgbado ọkụ laser nwere ọgụgụ isi ugbu a maka nhazi trajectory tupu ịgbado ọkụ na nsochi na nyocha ogo ịgbado ọkụ.N'ụlọ na ná mba ọzọ, nnyocha na nchọpụta ntụpọ ịgbado ọkụ na parameter adaptive akara ka na-na mbụ ogbo, na laser ịgbado ọkụ usoro parameter adaptive akara technology ka etinyere na ụgbọ ala ahu imeputa.

Ya mere, na echiche nke ngwa e ji mara laser ịgbado ọkụ technology na usoro nke ụgbọala ahu ịgbado ọkụ, onye nwere ọgụgụ isi usoro maka ịgbado ọkụ laser na elu multi-sensọ dị ka isi na a elu-ọsọ na elu-nkenke ịgbado ọkụ robot njikwa usoro kwesịrị ịbụ. mepụtara n'ọdịnihu iji hụ na ezigbo oge na izi ezi nke akụkụ niile nke teknụzụ ịgbado ọkụ laser nwere ọgụgụ isi.Mepee njikọ nke "atụmatụ trajectory trajectory tupu ịgbado ọkụ - parameter adaptive control of welding quality online detection after welding" iji hụ na nhazi dị elu na nke ọma.

Oge nzipu: Ọktoba 16-2023