Ọchịchọ maka ígwè na ọha mmadụ nke oge a na-abawanye ụba mgbe niile.Na ndụ kwa ụbọchị, ọtụtụ ihe na-eji ígwè, na ọtụtụ ọla enweghị ike ịwụ n'otu oge.Ya mere, ọ dị mkpa iji ọkụ eletrik maka ịgbado ọkụ.Ọrụ nke electrode na usoro ịgbado ọkụ eletrik dị ezigbo mkpa.

The ịgbado ọkụ mkpanaka na-ike na gbazee na elu okpomọkụ n'oge arc ịgbado ọkụ, na jupụta nkwonkwo nke ịgbado ọkụ workpiece.Na-emekarị, kwekọrọ ekwekọ electrode na-ahọrọ dị ka ihe onwunwe nke ịgbado ọkụ workpiece.Enwere ike iji mkpanaka ịgbado ọkụ maka ịgbado otu ụdị ígwè ma ọ bụ ịgbado ọkụ n'etiti ígwè dị iche iche.

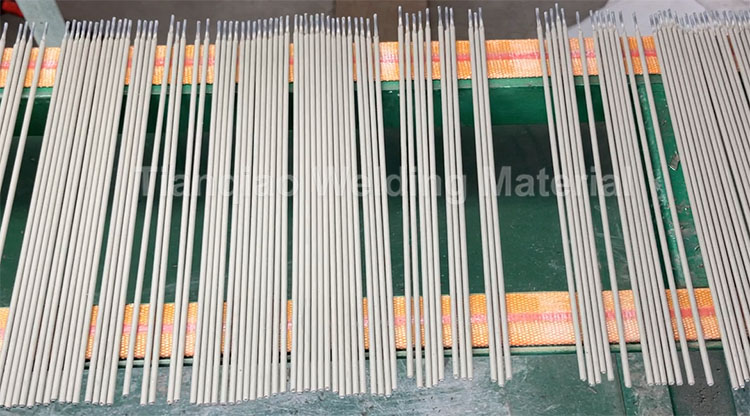

Ọdịdị nke Welding Electrode

Ihe mejupụtara ígwè dị n'ime nke mkpanaka ịgbado ọkụ na mkpuchi mpụga.Isi ịgbado ọkụ bụ waya ígwè nwere ụfọdụ dayameta na ogologo.Isi ọrụ nke ịgbado ọkụ isi bụ iduzi ugbu a ka ikpo ọkụ na gbazee, na jupụta na jikọọ workpiece.

Enwere ike kewaa isi ihe eji agbado ọkụ na carbon steel, alloy steel na igwe anaghị agba nchara.Otú ọ dị, iji mezuo ihe ndị a chọrọ n'ịgbado ọkụ, e nwere ihe pụrụ iche a chọrọ maka ihe onwunwe na ihe ndị dị na ígwè nke isi ịgbado ọkụ, na e nwere ụkpụrụ siri ike na ọdịnaya nke ihe ụfọdụ ígwè.N'ihi na ihe mejupụtara ígwè nke isi ịgbado ọkụ ga-emetụta àgwà nke weld ozugbo.

A ga-enwe mkpuchi mkpuchi n'èzí nke electrode, nke a na-akpọ mkpuchi flux.Uwe Flux na-arụ ọrụ dị mkpa.Ọ bụrụ na eletriki ịgbado ọkụ isi na-eji ozugbo weld na workpiece, ikuku na ndị ọzọ bekee ga-abanye a wụrụ awụ metal nke electric ịgbado ọkụ isi, na a chemical mmeghachi omume ga-eme na wụrụ awụ metal na-eme ka weld ozugbo.Nsogbu dị mma dị ka pores na mgbawa ga-emetụta ike ịgbado ọkụ.Uwe Flux nwere ihe pụrụ iche ga-ere ere ma gbazee n'ime gas na slag na okpomọkụ dị elu, nke nwere ike igbochi ikuku ịbanye ma melite ogo ịgbado ọkụ.

Ihe eji eme akwa mkpuchi na-agụnye: hydrochloric acid, fluoride, carbonate, oxide, organic matter, iron alloy na ndị ọzọ chemical powders, wdg, agwakọta dị ka usoro usoro.Ngwakọta mkpuchi nke ụdị mkpuchi electrode dị iche iche dịkwa iche.

Enwere ụdị atọ a na-ahụkarị, ya bụ slag agent, onye na-emepụta gas, na deoxidizer.

Onye na-ahụ maka slag bụ ngwakọta nke nwere ike ichebe igwe a wụrụ awụ site na ntinye ikuku mgbe agbazere electrode, si otú ahụ na-eme ka ịdị mma nke ịgbado ọkụ.

Ihe na-emepụta gas na-abụkarị nke starch na ntụ ọka osisi na ihe ndị ọzọ, nke nwere ogo nke mbelata.

Ihe mejupụtara deoxidizer bụ ferro-titanium na ferromanganese.N'ozuzu, ihe ndị dị otú ahụ nwere ike imeziwanye nguzogide iyi na nrụrụ nke ọla.

Tụkwasị na nke ahụ, e nwere ụdị mkpuchi ndị ọzọ na elu electrode, na nhazi na nha nke ụdị ọ bụla ga-adị iche.

Imepụta usoro nke ịgbado ọkụ electrode

Usoro mmepụta nke eriri ịgbado ọkụ bụ ịmepụta isi ihe na-edozi ahụ ma kwadebe mkpuchi dị ka ihe a chọrọ n'aka nke mkpara ịgbado ọkụ, ma tinye mkpuchi ahụ n'otu n'otu na isi ịgbado ọkụ iji mee ka o kwekọọ ihe ndị chọrọ imewe nke mkpara ịgbado ọkụ ruru eru.

Nke mbụ, a na-esi na igwe na-emepụta ihe na-akpụ akpụ akpụpụta, a na-ewepụ nchara nchara n'elu ígwè ahụ na igwe ahụ, mgbe ahụ, a na-agbatị ya.Igwe ahụ na-egbutu ogwe nchara n'ogologo nke electrode.

Na-esote, ọ dị mkpa ka a kwadebe mkpuchi n'elu electrode.A na-ekpuchi ihe dị iche iche nke ihe mkpuchi ahụ iji wepụ ihe ndị na-adịghị ọcha, wee wụsa ya n'ime igwe dị ka oke nha, na-agbakwunye ihe nkedo n'otu oge ahụ.Ngwa ngwa powdered niile na-agwakọta nke ọma site na mkpali nke igwe.

Tinye ntụ ntụ agwakọta n'ime ihe ebu ma pịa ya n'ime cylinder cylindrical nke nwere oghere okirikiri n'etiti.

Tinye ọtụtụ barel ndị a na-agbanye n'ime igwe, tinye cores ịgbado ọkụ nke ọma n'ọdụ ụgbọ mmiri nke igwe, ihe ndị na-agbado ọkụ na-abanye n'ime igwe si n'ọdụ ụgbọ mmiri na-abanye n'ọdụ ụgbọ mmiri, na cores agbamakwụkwọ na-agafe n'etiti gbọmgbọm n'ihi extrusion.Igwe ahụ na-agbasa ntụ ntụ na isi na-agafe ka ọ bụrụ mkpuchi.

N'oge usoro mkpuchi nke mkpanaka ịgbado ọkụ, a na-eji akwa mkpuchi kpuchie isi ihe niile.Iji mee ka electrode dị mfe ijide ma na-eduzi ọkụ eletrik, isi na ọdụ nke electrode kwesịrị ka a na-ehichapụ ya na mkpuchi iji kpughee isi ịgbado ọkụ.

Mgbe etinyere ihe mkpuchi ahụ, isi na-egweri na mkpanaka ịgbado ọkụ mgbe ọ gbachara ọdụ ahụ, a ga-edozi ya nke ọma na ígwè ígwè ma zigara ya na oven maka ihicha.

Iji nwee ike ịmata ọdịiche dị na nkọwapụta na ụdị nke electrode n'ụzọ dị mfe, ọ dị mkpa ibipụta na electrode.Mgbe mkpanaka ịgbado ọkụ ahụ na-agagharị na eriri ebufe, a na-eji igwe obibi akwụkwọ rọba na-ebipụta ya na eriri ebu.

Mgbe e bipụtachara ihe nlereanya nke ịgbado ọkụ, enwere ike ịchikọta mkpanaka ma ree ya mgbe ọ gafechara nyocha ahụ.

Tianqiao ika ịgbado ọkụ electrodes nwere magburu onwe arụmọrụ, mụ mma, mara ịgbado ọkụ ịkpụzi, na ezi slag mwepụ, ezi ike iguzogide nchara, Stomata na mgbape, ezi na ike edebe metal mechanics odide.Ihe ịgbado ọkụ Tianqiao ika na-ezute nnabata ndị ahịa n'ihi ọmarịcha mma, arụmọrụ pụtara ìhè na ọnụahịa asọmpi.pịa ebe aka ilelekwuo maka ngwaahịa anyị

Oge nzipu: Sep-03-2021