Q1: Gịnị bụ ịgbado ọkụ ihe?Kedu ihe a ga-agụnye?

Azịza: Ihe eji agbado ọkụ gụnyere mkpanaka ịgbado ọkụ, wires ịgbado ọkụ, fluxes, gas, electrodes, gaskets, wdg.

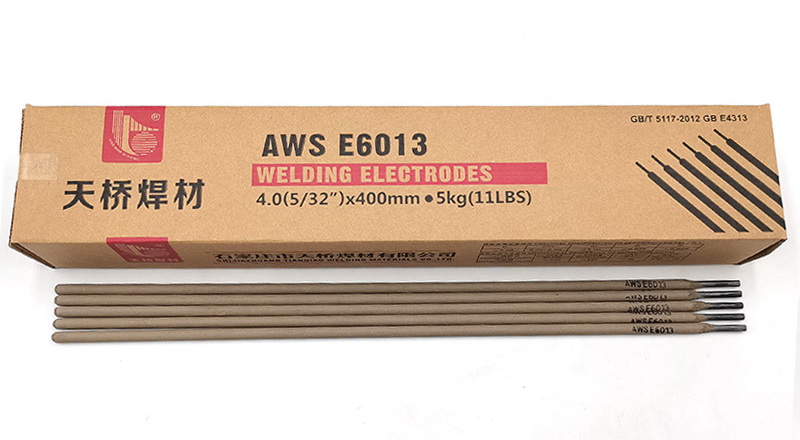

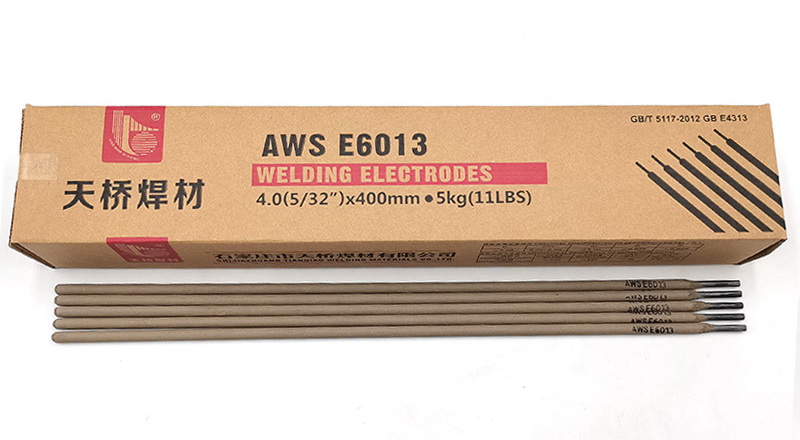

Q2: Gịnị bụ acid electrode?

Azịza: Ihe mkpuchi nke electrode acid nwere nnukwu acid oxides dị ka SiO2, TiO2 na ụfọdụ carbonate, na alkalinity nke slag bụ ihe na-erughị 1. Titanium electrodes, calcium titanium electrodes, ilmenite electrodes na ígwè oxide. electrodes bụ niile acid electrodes.

Q3: Gịnị bụ alkaline electrode?

Azịza: Ihe mkpuchi electrode alkaline nwere nnukwu ihe na-emepụta ihe na-emepụta ihe dịka marble, fluorite, wdg, ma nwee ụfọdụ deoxidizer na alloying agent.Ụdị electrodes dị ala bụ alkaline electrodes.

Q4: Gịnị bụ cellulose electrode?

Azịza: Ihe mkpuchi electrode nwere ọdịnaya cellulose dị elu na arc kwụsiri ike.Ọ na-emebi ma na-emepụta nnukwu gas iji chebe ígwè weld n'oge ịgbado ọkụ.Ụdị electrode a na-emepụta obere slag ma dị mfe iwepụ.A na-akpọkwa ya electrode ịgbado ọkụ kwụ ọtọ.Enwere ike ịgbado ya n'ọnọdụ niile, yana ịgbado ọkụ kwụ ọtọ nwere ike ịgbado ala.

Q5: Gini mere a ga-eji kpoo electrode nke ọma tupu ịgbado ọkụ?

Mkpanaka ịgbado ọkụ na-eme ka arụmọrụ nke usoro ahụ dịkwuo njọ n'ihi mmịpụta mmiri, na-ebute arc na-adịghị akwụsi ike, ụbara spatter, na mfe ịmepụta pores, cracks na ntụpọ ndị ọzọ.Ya mere, mkpanaka ịgbado ọkụ ga-akpọnwụ nke ọma tupu eji.N'ozuzu, ihicha okpomọkụ nke acid electrode bụ 150-200 ℃, na oge bụ 1 hour;na ihicha okpomọkụ nke alkaline electrode bụ 350-400 ℃, oge bụ 1-2 awa, na ọ na-akpọnwụ na-etinye na incubator na 100-150 ℃ N'ime, buru ya ka ị na-aga.

Q6: Gịnị bụ ịgbado ọkụ waya?

Azịza: Ọ bụ waya igwe a na-eji dị ka igwe na-ejuputa n'oge ịgbado ọkụ ma na-eduzi ọkụ eletrik n'otu oge a na-akpọ waya ịgbado ọkụ.Enwere ụdị abụọ: waya siri ike na waya flux-cored.Ụdị waya ịgbado ọkụ siri ike nke a na-ejikarị: (GB-national standard of China) ER50-6 (klas: H08Mn2SiA).(AWS-American Standard) ER70-6.

Q7: Gịnị bụ flux cored ịgbado ọkụ waya?

Azịza: Ụdị waya ịgbado ọkụ mere site na mkpa nchara ibe akpọrepu n'ime gburugburu ígwè ọkpọkọ ma jupụta na ụfọdụ mejupụtara nke ntụ ntụ.

Q8: Gịnị kpatara eriri carbon dioxide na-echebe waya flux cored?

Azịza: E nwere ụdị anọ nke flux-cored welding waya: acidic flux-cored gas na-echebe welding waya (ụdị titanium), alkaline flux-cored gas na-echebe ịgbado ọkụ waya (ụdị titanium calcium ụdị), metal ntụ ntụ ụdị flux-cored gas na-echebe ịgbado ọkụ waya na flux-coreed onwe-echebe welding waya.The ụlọ titanium ụdị flux-cored gas na-echebe ịgbado ọkụ waya na-adịkarị na-echebe site CO2 gas;A na-echekwa wired ịgbado ọkụ ndị ọzọ site na gas agwakọtara (biko rụtụ aka na nkọwapụta waya nwere flux).Mmeghachi omume metallurgical nke usoro slag gas ọ bụla dị iche, biko ejila gas nchebe na-ezighi ezi.Flux-cored ịgbado ọkụ waya gas slag jikọtara nchebe, ezigbo ịgbado ọkụ n'osisi, elu keukwu n'ibu Njirimara.

Q9: Gịnị mere e ji teknuzu chọrọ maka ịdị ọcha nke carbon dioxide gas?

Azịza: N'ozuzu, CO2 gas bụ ihe sitere na mmepụta kemịkalụ, na ịdị ọcha nke naanị ihe dịka 99.6%.O nwere ihe ndị na-adịghị ọcha na mmiri, nke ga-eweta ntụpọ dị ka pores na weld.Maka ngwaahịa ịgbado ọkụ dị mkpa, a ga-ahọrọ gas nwere ịdị ọcha CO2 ≥99.8%, na-enwe obere oghere na weld, ọdịnaya hydrogen dị ala, yana ezigbo mgbape mgbape.

Q10: Gịnị mere nwere elu oru chọrọ maka argon ịdị ọcha?

Azịza: Enwere ụdị argon atọ ugbu a n'ahịa: argon larịị (dị ọcha gburugburu 99.6%), argon dị ọcha (dị ọcha gburugburu 99.9%), na argon dị ọcha (99.99%) dị ọcha.Abụọ mbụ nwere ike welded na carbon ígwè na igwe anaghị agba nchara.A ghaghị iji argon dị ọcha mee ihe maka ịgbado ọla ndị na-adịghị ferrous dị ka aluminom na aluminom alloys, titanium na titanium alloys;iji zere oxidation nke weld na mpaghara okpomọkụ emetụtara, enweghị ike ịnweta nhazi weld dị elu ma mara mma.

Igwe ọkụ eletrik, igwe eletrik, igwe ịgbado ọkụ, igwe ịgbado ọkụ, igwe ịgbado ọkụ, mkpanaka ịgbado ọkụ, igwe ịgbado ọkụ, ọnụ ahịa elektrọd, ọnụ ahịa ụlọ ọrụ ịgbado ọkụ, mkpisi ịgbado ọkụ, osisi ịgbado ọkụ, osisi ịgbado ọkụ, mkpanaka ịgbado ọkụ, igwe ịgbado ọkụ, mkpanaka ọkụ eletrik, igwe ịgbado ọkụ, ihe mgbado ọkụ, ịgbado ọkụ erimeri, China electrode, ịgbado ọkụ electrodes China, carbon ígwè ịgbado ọkụ electrode, carbon ígwè ịgbado ọkụ electrodes, ịgbado ọkụ electrode factory, Chinese factory ịgbado ọkụ electrode, China ịgbado ọkụ electrode, China ịgbado ọkụ mkpanaka, ịgbado ọkụ mkpara, ịgbado ọkụ onunu, N'ogbe ịgbado ọkụ ọkọnọ, ụwa ịgbado ọkụ ọkọnọ ,Arc ịgbado ọkụ ọkọnọ, ịgbado ọkụ ihe ọkọnọ, arc ịgbado ọkụ, ígwè ịgbado ọkụ, mfe arc ịgbado ọkụ electrode, arc ịgbado ọkụ electrode, arc ịgbado ọkụ electrode, vetikal ịgbado ọkụ electrode, price nke ịgbado ọkụ electrodes, ọnụ ala ịgbado ọkụ electrode, acid ịgbado ọkụ electrodes, alkaline ịgbado ọkụ electrode, cellulos. welding electrode, china ịgbado ọkụ electrodes, factory electrode, obere size ịgbado ọkụ electrodes, ịgbado ọkụ ihe, ịgbado ọkụ ihe, ịgbado ọkụ mkpanaka ihe, ịgbado ọkụ electrode njide, nickel ịgbado ọkụ mkpanaka, j38.12 e6013, ịgbado ọkụ mkpara e7018-1, ịgbado ọkụ mkpanaka electrode, ịgbado ọkụ mkpanaka 6010, ịgbado ọkụ e6010, ịgbado ọkụ mkpara e7018, ịgbado ọkụ mkpara e6011, ịgbado ọkụ mkpara e7018, ịgbado ọkụ electrodes 7018, ịgbado ọkụ mkpara 6013, ịgbado ọkụ mkpanaka 6013, ịgbado ọkụ eletrik, 3013 electrode 0601 welding electrode, 6011 igwe na-agbado ọkụ, 6011 electrodes, 6013 ịgbado ọkụ, 6013 ịgbado ọkụ, 6013 welding electrodes, 6013 electrodes,7024 welding 7016,7018 welding ,7018 electrodes , ịgbado ọkụ electrode e7016,e6010 mkpanaka ịgbado ọkụ,e6011 ịgbado ọkụ mkpanaka,e6013 ịgbado ọkụ mkpanaka,e7018 ịgbado ọkụ mkpara,e6013 ịgbado ọkụ electrodes,e7018 ịgbado ọkụ electrode,e7018 ịgbado ọkụ electrodes,e7018 ịgbado ọkụ electrodes,J42 , wholesale e6010, n'ogbe e6011, N'ogbe e6013, N'ogbe e7018, kasị mma ịgbado ọkụ electrode, kasị mma ịgbado ọkụ electrode J421, igwe anaghị agba nchara electrode, igwe anaghị agba nchara, igwe anaghị agba nchara, igwe anaghị agba nchara, igwe anaghị agba nchara, SS ịgbado ọkụ electrode, ịgbado ọkụ mkpanaka e307, ịgbado ọkụ electrode 3912 electrode ,e316l 16 welding electrodes, cast iron welding electrode,aws Eni-Ci,aws Enife-Ci,surfacing ịgbado ọkụ,ike chere ihu ịgbado ọkụ mkpanaka,ike surfacing ịgbado ọkụ,hardfacing ịgbado ọkụ, ịgbado ọkụ, ịgbado ọkụ,vautid ịgbado ọkụ,bohler ịgbado ọkụ,lcoder welding, ịgbado ọkụ, Atlantic ịgbado ọkụ, ịgbado ọkụ, flux ntụ ntụ, ịgbado ọkụ flux, ịgbado ọkụ ntụ ntụ, ịgbado ọkụ electrode flux ihe onwunwe, ịgbado ọkụ electrode flux, ịgbado ọkụ electrode ihe, tungsten electrode, tungsten electrodes, ịgbado ọkụ waya, argon arc ịgbado ọkụ, mig ịgbado ọkụ, tig ịgbado ọkụ, gas arc ịgbado ọkụ, gas metal arc ịgbado ọkụ, eletrik na-agbado ọkụ, eletriki aak ịgbado ọkụ, arc ịgbado ọkụ mkpara, carbon arc ịgbado ọkụ, e6013 ịgbado ọkụ mkpanaka eji, ụdị nke ịgbado ọkụ electrodes, flux isi ịgbado ọkụ, ụdị electrodes na ịgbado ọkụ, ịgbado ọkụ ọkọnọ, ịgbado ọkụ metal, metall. ịgbado ọkụ, Shielded metal arc ịgbado ọkụ, aluminum ịgbado ọkụ, ịgbado ọkụ aluminum na mig, aluminum mig ịgbado ọkụ, ọkpọkọ ịgbado ọkụ, ịgbado ọkụ ụdị, ụdị nke ịgbado ọkụ mkpanaka, niile ụdị ịgbado ọkụ, ịgbado ọkụ mkpara, 6013 ịgbado ọkụ mkpara amperage, ịgbado ọkụ mkpara electrodes, ịgbado ọkụ electrode nkọwapụta, ịgbado ọkụ nkesa electrode, ịgbado ọkụ electrode aluminum, ịgbado ọkụ electrode dayameta, nwayọọ ígwè ịgbado ọkụ, igwe anaghị agba nchara, e6011 ịgbado ọkụ mkpanaka eji, ịgbado ọkụ mkpara nha, ịgbado ọkụ mkpanaka mkpara, ịgbado ọkụ electrodes size, aws e6013, aws e7018, aws , 6011 igwe anaghị agba nchara, igwe anaghị agba nchara mig welding waya, tig ịgbado ọkụ waya, ala temp ịgbado ọkụ mkpanaka, 6011 ịgbado ọkụ mkpanaka amperage, 4043 ịgbado ọkụ mkpanaka, nkedo ịgbado ọkụ mkpanaka, Western ịgbado ọkụ Academy, Sanrico ịgbado ọkụ mkpanaka, aluminum ịgbado ọkụ, aluminum rodi ịgbado ọkụ ngwaahịa, ịgbado ọkụ tech, ịgbado ọkụ factory

Oge nzipu: Jun-23-2021