Ihe mgbakasị ahụ fọdụrụnụ na-akpata site na nkesa okpomọkụ na-enweghị isi nke weldment kpatara site na ịgbado ọkụ, mgbasawanye ọkụ na mkpirisi nke ígwè weld, wdg, ya mere nrụnye ịgbado ọkụ ga-emepụta nrụgide fọdụrụnụ.

Ụzọ kachasị mma iji kpochapụ nrụgide fọdụrụnụ bụ okpomọkụ dị elu, ya bụ, kpo oku weldment na ọnọdụ okpomọkụ ma jide ya ruo oge ụfọdụ n'ime ọkụ ọgwụgwọ okpomọkụ, na iji mbelata njedebe mkpụrụ nke ihe ahụ. na elu okpomọkụ na-eme ka plastik na-asọba n'ebe ndị nwere nrụgide dị n'ime.Nrụrụ na-agbanwe agbanwe ji nwayọọ nwayọọ na-ebelata, na nrụrụ plastik ji nwayọọ nwayọọ na-abawanye iji belata nchekasị.

1.Nhọrọ nke usoro ọgwụgwọ okpomọkụ

Mmetụta nke ọgwụgwọ okpomọkụ nke post-weld na ike nkwụsị na njedebe nke ígwè na-ejikọta ya na okpomọkụ ọgwụgwọ okpomọkụ na ijide oge.Mmetụta nke ọgwụgwọ okpomọkụ post-weld na mmetụta siri ike nke weld metal dịgasị iche iche na ụdị ígwè dị iche iche.

Ọgwụgwọ okpomọkụ mgbe e mesịrị weld na-anakwere otu okpomọkụ dị elu ma ọ bụ normalizing gbakwunyere okpomọkụ dị elu.Maka nkwonkwo ịgbado ọkụ gas, a na-anabata normalizing na okpomọkụ dị elu.Nke a bụ n'ihi na ọka nke gas ịgbado ọkụ seam na okpomọkụ-emetụta mpaghara bụ keadighi rarii, na ọka kwesịrị nụchaa, ya mere normalizing ọgwụgwọ nakweere.

Otú ọ dị, otu normalizing enweghị ike iwepụ nrụgide fọdụrụnụ, ya mere a chọrọ okpomọkụ dị elu iji wepụ nchekasị.A otu ọkara-okpomọkụ tempering bụ naanị adabara mgbakọ na ịgbado ọkụ nke nnukwu nkịtị obere carbon ígwè containers kpọkọtara na saịtị, na nzube ya bụ iji nweta ele mmadụ anya n'ihu mkpochapụ nke fọdụrụ nrụgide na dehydrogenation.

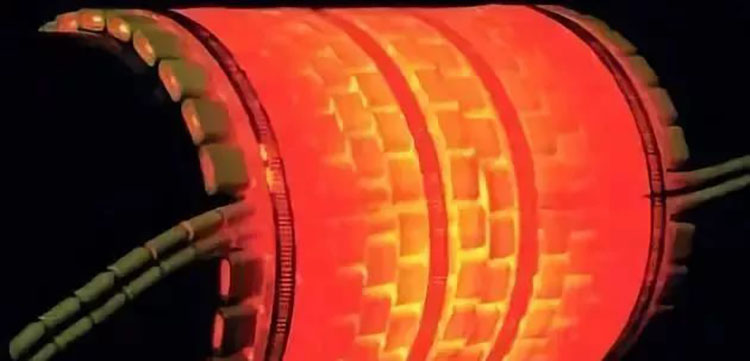

N'ọtụtụ ọnọdụ, a na-eji otu okpomọkụ dị elu mee ihe.Igwe ọkụ na ikpo ọkụ nke ọgwụgwọ okpomọkụ ekwesịghị ịdị ngwa ngwa, na mgbidi dị n'ime na n'èzí kwesịrị ịdị n'otu.

2.Usoro ọgwụgwọ okpomọkụ na-eji na arịa nrụgide

E nwere ụdị ụzọ ọgwụgwọ okpomọkụ abụọ maka arịa nrụgide: otu bụ ọgwụgwọ okpomọkụ iji meziwanye ihe eji arụ ọrụ;nke ọzọ bụ ọgwụgwọ okpomọkụ post-weld (PWHT).N'ikwu ya n'ụzọ sara mbara, post-weld okpomọkụ ọgwụgwọ bụ okpomọkụ ọgwụgwọ nke welded ebe ma ọ bụ welded components mgbe workpiece bụ welded.

Ọdịnaya a kapịrị ọnụ na-agụnye mgbakasị ahụ mgbakasị ahụ, mgbakasị ahụ zuru oke, ngwọta siri ike, normalizing, normalizing gbakwunyere iwe ọkụ, iwe ọkụ, enyemaka nchekasị dị ala, ọgwụgwọ okpomọkụ mmiri ozuzo, wdg.

N'echiche dị warara, ọgwụgwọ okpomọkụ nke post-weld na-ezo aka naanị na mgbakasị ahụ mgbakasị ahụ, ya bụ, iji meziwanye arụmọrụ nke mpaghara ịgbado ọkụ ma kpochapụ mmetụta ndị na-emerụ ahụ dị ka nrụgide ịgbado ọkụ, ka ọ bụrụ otu na n'ụzọ zuru oke ikpo ọkụ mpaghara ịgbado ọkụ. na akụkụ ndị metụtara ya n'okpuru metal frasi mgbanwe 2 okpomọkụ ebe , na mgbe ahụ usoro nke edo jụrụ.N'ọtụtụ ọnọdụ ọgwụgwọ okpomọkụ postweld a tụlere bụ n'ezie ọgwụgwọ mgbakasị mgbakasị ahụ.

3.Ebumnuche nke ọgwụgwọ okpomọkụ post weld

(1).Wetuo obi mgbakasị ahụ fọdụrụnụ.

(2).Mee ka ọdịdị na nha nke usoro ahụ guzosie ike ma belata mgbagwoju anya.

(3).Melite arụmọrụ nke metal ntọala na nkwonkwo welded, gụnyere:

a.Melite plasticity nke igwe weld.

b.Belata ike nke mpaghara okpomọkụ metụtara.

c.Melite ike mgbaji.

d.Melite ike ike ọgwụgwụ.

e.Weghachite ma ọ bụ mụbaa ike mkpụrụ belatara na nhazi oyi.

(4).Meziwanye ikike iguzogide mmebi nrụgide.

(5).Hapụkwa gas na-emerụ ahụ n'ime igwe weld, ọkachasị hydrogen, iji gbochie ihe mgbawa na-egbu oge.

4.Mkpebi nke mkpa PWHT

Ma post-weld okpomọkụ ọgwụgwọ dị mkpa maka arịa mgbali kwesịrị n'ụzọ doro anya kpọmkwem na imewe, nke a chọrọ site ugbu a nrụgide arịa imewe koodu.

Maka arịa nrụgide welded, enwere nnukwu nrụgide fọdụrụ na mpaghara ịgbado ọkụ, yana mmetụta ọjọọ nke nrụgide fọdụrụnụ.Gosiri naanị n'okpuru ọnọdụ ụfọdụ.Mgbe nrụgide fọdụrụnụ na-ejikọta ya na hydrogen na weld, ọ ga-akwalite ike nke mpaghara okpomọkụ na-emetụta, na-eme ka ọgbọ nke oyi na-atụ oyi na-egbu oge.

Mgbe a na-ejikọta nrụgide static fọdụrụ na weld ma ọ bụ nrụgide dị ike na-arụ ọrụ na-arụ ọrụ na-arụ ọrụ na-eme ka ọ bụrụ ihe na-emerụ emerụ nke ọkara, ọ nwere ike ime ka ọkpụkpụ gbawaa, nke a na-akpọ corrosion nrụgide.Nchegbu fọdụrụnụ na ịgbado ọkụ na isi ike igwe mgbado ọkụ kpatara bụ ihe dị mkpa maka mgbawa corrosion nrụgide.

Nsonaazụ nyocha na-egosi na isi ihe na-akpata nrụrụ na nrụgide fọdụrụnụ na ihe ndị e ji ígwè rụọ bụ ime ka ígwè ahụ gbanwee site na nrụrụ otu n'otu gaa na corrosion mpaghara, ya bụ, corrosion intergranular ma ọ bụ transgranular corrosion.N'ezie, ma corrosion cracking na intergranular corrosion nke ọla na-eme na mgbasa ozi nwere ụfọdụ àgwà maka na metal.

N'ebe ọnụnọ nke nrụgide fọdụrụnụ, ọ dị iche iche dịka ihe mejupụtara, itinye uche na okpomọkụ nke ihe na-emebi emebi, yana ọdịiche dị na nhazi, nhazi, ọnọdụ elu, ọnọdụ nrụgide, wdg nke metal ntọala na mpaghara ịgbado ọkụ. , ka corrosion ọdịdị nke mmebi ahụ nwere ike gbanwee.

5.Ntụle mmetụta zuru oke nke PWHT

Ọgwụgwọ okpomọkụ mgbe e mesịrị weld adịghị aba uru nke ukwuu.N'ozuzu, ọgwụgwọ okpomọkụ post-weld bara uru maka ịkwụsị nrụgide fọdụrụnụ, a na-eme ya naanị mgbe enwere ihe siri ike chọrọ maka corrosion nrụgide.Otú ọ dị, mmetụta siri ike ule nke ihe atụ na-egosi na post-weld ọgwụgwọ okpomọkụ adịghị mma maka ịdị ike nke metal echekwara na weld okpomọkụ-emetụta mpaghara, na mgbe ụfọdụ intergranular cracking nwere ike ime n'ime ọka coarsening nso nke weld okpomọkụ- mpaghara emetụtara.

Ọzọkwa, PWHT na-adabere na mbelata ike ihe onwunwe na oke okpomọkụ iji nweta enyemaka nchekasị.Ya mere, n'oge PWHT, ihe owuwu ahụ nwere ike hapụ isi ike.Maka ihe owuwu ndị na-agbaso PWHT n'ozuzu ma ọ bụ akụkụ, a ga-atụle welded na okpomọkụ dị elu tupu ọgwụgwọ okpomọkụ.ikike nkwado.

Ya mere, mgbe ị na-atụle ma a ga-eme ọgwụgwọ okpomọkụ post-weld, uru na ọghọm nke ọgwụgwọ okpomọkụ kwesịrị iji ya tụnyere ya.Site n'echiche nke arụmọrụ nhazi, enwere otu akụkụ iji melite arụmọrụ, na akụkụ nke ọzọ iji belata arụmọrụ.Ekwesịrị ime mkpebi ezi uche dị na ya dabere na nleba anya nke ọma n'akụkụ abụọ ahụ.

Oge nzipu: Jun-20-2023