Electrode arc ịgbado ọkụ bụ usoro ịgbado ọkụ na-ejikarị eme ihe na mmepụta ụlọ ọrụ.Igwe a ga-agbado bụ otu osisi, na electrode bụ ogwe nke ọzọ.Mgbe okporo osisi abụọ ahụ dị nso, a na-emepụta arc.A na-eji ọkụ na-emepụta site na mgbawa arc (nke a na-akpọkarị arc combustion) iji jikọọ electrode na workpieces agbazekwa ibe ya wee mepụta weld mgbe condensing gasịrị, nke mere na iji nweta usoro ịgbado ọkụ na nkwonkwo siri ike.

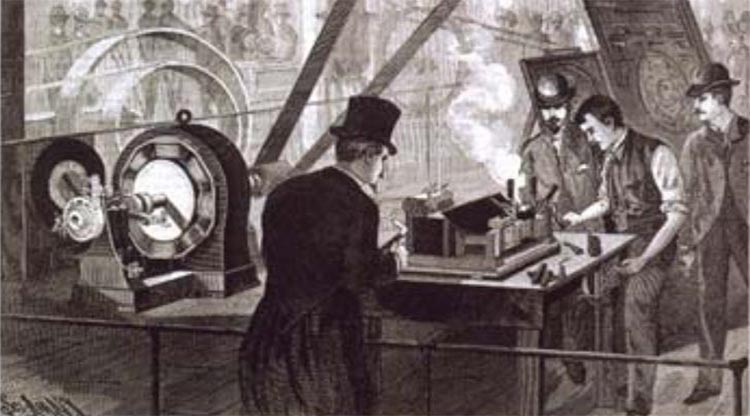

Ọgụgụ 1. Akụkọ ihe mere eme nke ịgbado ọkụ

Akụkọ dị nkenke

Mgbe ọtụtụ nnwale ịgbado ọkụ dị ka narị afọ nke 19, otu onye England aha ya bụ Willard bu ụzọ nweta patent maka ịgbado ọkụ n’afọ 1865. O ji ọkụ eletrik gafere n’obere iberibe ígwè abụọ iji jikọta ha nke ọma, ma n’ihe dị ka afọ iri abụọ ka nke ahụ gasịrị, onye Russia. aha ya bụ Bernard nwetara patent maka usoro ịgbado ọkụ arc.O debere arc n'etiti mkpanaka carbon na ihe ndị a na-arụ ọrụ.Mgbe a na-eji aka na-arụ ọrụ arc site na nkwonkwo nke ihe ndị a na-arụ ọrụ, a na-ejikọta ihe ndị a ga-eji welded ọnụ.N'afọ ndị 1890, e mepụtara ígwè siri ike dị ka electrode, nke a na-eri na ọdọ mmiri a wụrụ awụ wee ghọọ akụkụ nke ígwè weld.Otú ọ dị, oxygen na nitrogen dị n'ikuku kpụrụ oxides na-emerụ ahụ na nitrides na ígwè weld., Ya mere na-eduga na ogbenye ịgbado ọkụ àgwà.

Na mmalite narị afọ nke 20, mkpa ọ dị ichebe arc iji zere ịbanye n'ikuku ka achọpụtala, na iji ọkụ ọkụ na-eme ka ihe mkpuchi ahụ dị n'ime electrode nke mkpuchi gas nchebe ghọrọ usoro kachasị mma.N'etiti 1920s, e mepụtara electrode mkpuchi, nke mere ka mma nke ígwè welded dịkwuo mma.N'otu oge ahụ, ọ pụkwara ịbụ mgbanwe kachasị mkpa nke ịgbado ọkụ arc.Ngwá ọrụ bụ isi na usoro ịgbado ọkụ gụnyere igwe ịgbado ọkụ eletrik, ihe mgbado ọkụ na ihe mkpuchi ihu.

Ọgụgụ 2. Ụkpụrụ nke ịgbado ọkụ

Ọgụgụ 2. Ụkpụrụ nke ịgbado ọkụ

Ụkpụrụ

A na-akwado arc ịgbado ọkụ site na isi iyi ike ịgbado ọkụ.N'okpuru omume nke ụfọdụ voltaji, a siri ike na-adịgide adịgide mwepu onu pụtara n'etiti electrode (na njedebe nke ịgbado ọkụ waya ma ọ bụ ịgbado ọkụ mkpanaka) na workpiece.Ihe kachasị mkpa nke ịgbado ọkụ bụ ikuku gas, ya bụ, gas na-anọpụ iche na oghere ebe arc dị na-emebi n'ime ion nke ọma na ebubo electrons na-ezighị ezi n'okpuru ọrụ nke ụfọdụ voltaji, nke a na-akpọ ionization.A na-eduzi ihe abụọ ndị a ebubo ebubo na okporo osisi abụọ ahụ.Ntugharị ụzọ na-eme ka gas mpaghara na-eduzi ọkụ eletrik ka ọ bụrụ arc.Igwe ọkụ eletrik na-agbanwe ike eletrik ka ọ bụrụ okpomọkụ, nke na-ekpo ọkụ ma na-agbaze ígwè ahụ iji mepụta nkwonkwo welded.

Mgbe arc na-eme ka ọ bụrụ "ịkụnye", usoro nkwụsị ahụ n'onwe ya nwere ike ịmepụta ihe ndị a na-akwụ ụgwọ dị mkpa iji kwado nkwụsị ahụ, nke bụ ihe nkwụsị nke onwe ya.Na usoro mgbapu arc nwere obere voltaji, elu dị ugbu a, oke okpomọkụ na ọkụ ọkụ siri ike.Site na usoro a, a na-agbanwe ike eletrik ka ọ bụrụ ọkụ, ígwè ọrụ na ike ọkụ.Welding tumadi na-eji ya thermal na n'ibu ike imezu nzube nke ejikọta ọla.

N'oge ịgbado ọkụ, aak ọkụ n'etiti ịgbado ọkụ mkpanaka na ịgbado ọkụ workpieces, agbaze workpieces na electrode isi na-etolite a wụrụ awụ ọdọ mmiri.N'otu oge ahụ, a na-agbazekwa mkpuchi electrode, na mmeghachi omume kemịkalụ na-emepụta slag na gas, nke na-echebe njedebe nke electrode, ụmụ irighiri mmiri, ọdọ mmiri a wụrụ awụ na ígwè weld dị elu.

Isi nhazi

Ụzọ ịgbado ọkụ a na-ahụkarị gụnyere Shielded Metal Arc Welding (SMAW), Submerged Arc Welding (SAW), Gas Tungsten Arc Weld (GTAW ma ọ bụ TIG welding), Plasma Arc Welding (PAW) na Gas Metal Arc Welding (GMAW,MIG ma ọ bụ MAG ịgbado ọkụ). ) wdg.

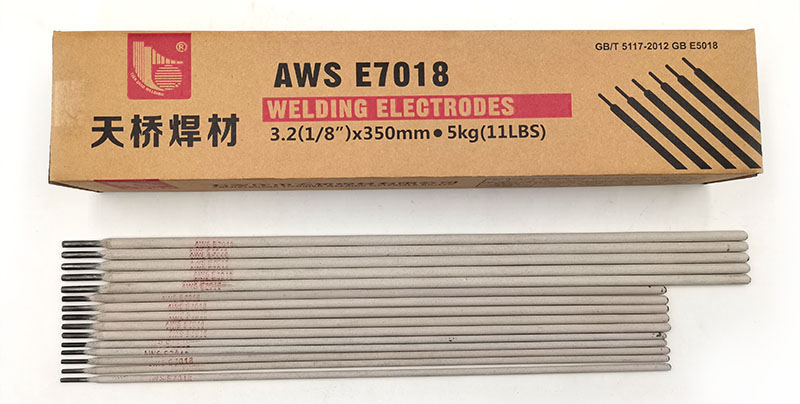

Ọgụgụ 3. E7018 welding electrode

Mgbado ọkụ igwe mkpuchi mkpuchi (SMAW)

Shielded metal arc ịgbado ọkụ na-eji electrode na workpiece dị ka abụọ electrodes, na okpomọkụ na ịfụ ike nke aak na-eji na mpaghara agbaze workpiece n'oge ịgbado ọkụ.N'otu oge ahụ, n'okpuru ọrụ nke arc okpomọkụ, njedebe nke electrode na-agbaze ka ọ bụrụ droplet, na workpiece na-agbaze akụkụ ụfọdụ iji mepụta olulu oval jupụtara na mmiri mmiri.Igwe mmiri a wụrụ awụ na ntụpọ nke workpiece na-etolite ọdọ mmiri a wụrụ awụ.N'oge usoro ịgbado ọkụ, mkpuchi na ndị na-abụghị metal bụ inclusions igbari ibe ha na-etolite a na-abụghị ọla ihe na-ekpuchi elu nke weld site kemịkalụ mgbanwe a na-akpọ slag.Ka arc na-aga, ọdọ mmiri ahụ a wụrụ awụ na-ajụkwa oyi ma gbasie ike ka ọ bụrụ weld.Anyị nwere electrode ịgbado ọkụ dị iche iche maka SMAW, ụdị kachasị ewu ewu bụE6010, E6011, E6013, E7016, E7018, na makaigwe anaghị agba nchara, nkedo ígwè, ike surfacingwdg.

Onyonyo 4. Ngwunye ịgbado ọkụ n'okpuru mmiri

Onyonyo 4. Ngwunye ịgbado ọkụ n'okpuru mmiri

Mgbado ọkụ n'ime mmiri (SAW)

Mgbado ọkụ n'okpuru mmiri bụ usoro nke arc na-ere ọkụ n'okpuru oyi akwa flux maka ịgbado ọkụ.Igwe elektrọd igwe eji agbado arc mmiri dị n'ime mmiri bụ waya efu nke a na-enye nri na-akpaghị aka na-enweghị nkwụsị.N'ozuzu, a na-eji trolley ịgbado ọkụ ma ọ bụ ngwaọrụ ndị ọzọ na-arụ ọrụ na eletriki iji ghọta mmegharị akpaka nke arc n'oge usoro ịgbado ọkụ.Akụ nke ịgbado ọkụ n'okpuru mmiri na-ere ọkụ n'okpuru granular flux.Okpomọkụ nke arc na-agbaze ma na-ekpochapụ akụkụ ndị arc nke workpiece na-eme kpọmkwem, njedebe nke waya ịgbado ọkụ na flux, na uzuoku nke metal na flux evaporates na-etolite oghere mechiri emechi gburugburu arc.Ọkụ n'ime oghere a.Ihe nkiri slag nke ejiri slag mepụtara site na mgbaze na-agbaze gburugburu oghere ahụ.Ihe nkiri slag a abụghị nanị na-ekewa ikuku nke ọma site na kọntaktị na arc na ọdọ mmiri a wụrụ awụ, kamakwa na-egbochi arc ahụ ịpụpụ.The ịgbado ọkụ waya kpụ ọkụ n'ọnụ na gbazee site aak dara n'ụdị ụmụ irighiri mmiri na mixes na wụrụ awụ workpiece metal na-etolite a wụrụ awụ ọdọ mmiri.Slag dị obere obere na-ese n'elu ọdọ mmiri a wụrụ awụ.Na mgbakwunye na ikewapụ n'ibu na nchebe nke ọla ọdọ mmiri a wụrụ awụ, slag ahụ a wụrụ awụ na-enwetakwa mmeghachi omume ọla na ọla ọdọ mmiri ahụ gbazere n'oge usoro ịgbado ọkụ, si otú ahụ na-emetụta ihe mejupụtara kemịkalụ nke igwe weld ahụ.Akụ ahụ na-aga n'ihu, ọla ọdọ mmiri ahụ a wụrụ awụ ji nwayọọ nwayọọ dajụọ ma mee ka ọ bụrụ weld.Mgbe slag a wụrụ awụ nke na-ese n'elu akụkụ ọdọ mmiri a wụrụ awụ jụrụ oyi, a na-emepụta eriri slag iji nọgide na-echebe weld ahụ na okpomọkụ dị elu ma gbochie ya ịbụ oxidized.Anyị na-enye mgbanwe maka SAW,SJ101,SJ301,SJ302

Ọgụgụ 5. Gas Tungsten Arc Weld-TIG

Ọgụgụ 5. Gas Tungsten Arc Weld-TIG

Gas Tungstna Arc Weld/Tungsten Inert Gas Welding (GTAW ma ọ bụ TIG)

welding TIG na-ezo aka na usoro ịgbado ọkụ nke arc nke na-eji tungsten ma ọ bụ tungsten alloy (thorium tungsten, cerium tungsten, wdg) dị ka electrode na argon dị ka gas na-echebe, nke a na-akpọ TIG welding ma ọ bụ GTAW ịgbado ọkụ.N'oge ịgbado ọkụ, e nwere ike ịgbakwunye filler metal ma ọ bụ tinye ya dị ka uzo uzo nke weld na arụmọrụ nke weld metal.A na-esikarị n'ihu arc agbakwunye ígwè na-ejuputa.N'ihi ihe pụrụ iche nke aluminom-magnesium na ihe alloy ya, AC tungsten arc welding ka achọrọ maka ịgbado ọkụ, yana DC tungsten arc na-eji maka ihe ọla ndị ọzọ.Iji chịkwaa ntinye ọkụ, pulsed argon tungsten arc welding na-ejikarị eme ihe.Waya ịgbado ọkụ TIG a na-ejikarị bụAWS ER70S-6, ER80S-G,ER4043,ER5356,HS221na wdg.

Ọgụgụ 5. Plasma Arc Welding

Ọgụgụ 5. Plasma Arc Welding

Plasma Arc Welding (PAW)

Plasma arc bụ ụdị arc pụrụ iche.Akụ ahụ bụkwa tungsten ma ọ bụ tungsten alloy (thorium tungsten, cerium tungsten, wdg) dị ka arc electrode, na-eji argon dị ka gas na-echebe, ma tungsten electrode adịghị agbatị na nozzle, ma retract N'ime nozzle, nozzle. bụ mmiri na-ajụ oyi, nke a makwaara dị ka mmiri oyi.A na-ekewa gas inert n'ime akụkụ abụọ, otu akụkụ bụ gas na-esi n'etiti tungsten electrode na mmiri oyi na-eme ka mmiri dị jụụ, nke a na-akpọ ion gas;akụkụ nke ọzọ bụ gas a na-awụpụ n'etiti oghere mmiri na-eme ka mmiri dị jụụ na mkpuchi gas nchebe, nke a na-akpọ Shielding gas, na-eji plasma arc dị ka ihe na-ekpo ọkụ maka ịgbado ọkụ, ịcha, ịgbasa, ịwụ elu, wdg.

Ọgụgụ 5 Mgbado ọkụ igwe-Inert Gas

Ọgụgụ 5 Mgbado ọkụ igwe-Inert Gas

Mgbado ọkụ igwe anaghị agba nchara (MIG)

MIG ịgbado ọkụ pụtara na ịgbado ọkụ waya dochie tungsten electrode.Igwe ịgbado ọkụ n'onwe ya bụ otu n'ime okporo osisi nke arc, na-arụ ọrụ nke eletriki eletrik na arcing, na n'otu oge ahụ dị ka ihe na-ejuputa, nke a na-agbaze mgbe niile ma jupụta n'ime weld n'okpuru omume nke arc.Igwe nchekwa nke a na-ejikarị gburugburu arc nwere ike ịbụ gas inert Ar, gas CO na-arụ ọrụ2, ma ọ bụ Ar + CO2ngwakọta gas.MIG ịgbado ọkụ nke na-eji Ar dị ka ihe nchebe gas ka a na-akpọ MIG ịgbado ọkụ;MIG welding nke na-eji CO2dị ka shielding gas a na-akpọ CO2ịgbado ọkụ.MIG kacha ewu ewu bụAWS ER70S-6, ER80S-G.

Oge nzipu: Ọgọst-17-2021