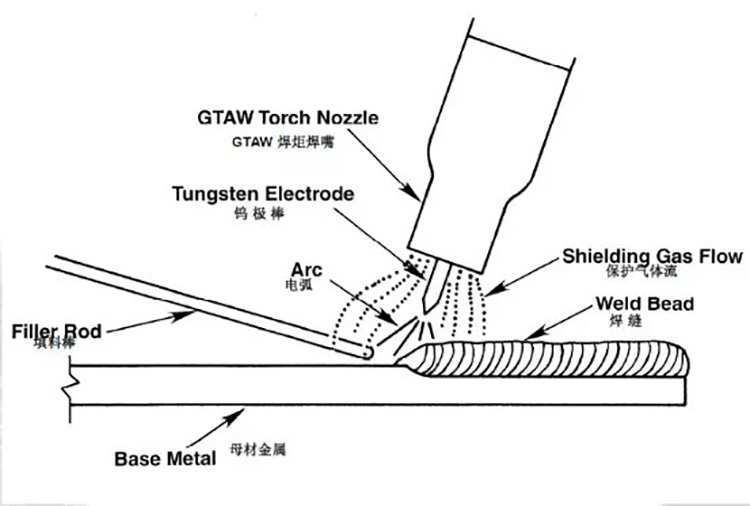

Argon tungsten arc welding na-eji argon dị ka gas na-echebe ọkụ na gbazee ihe ịgbado ọkụ n'onwe ya (ọ na-agbazekwa mgbe a na-agbakwunye metal filler) site na arc emepụtara n'etiti tungsten electrode na weld ahụ, wee mepụta ịgbado ọkụ. nke weld metal Way.Nketungsten electrode,Weld ọdọ mmiri, arc na ebe nkwonkwo na-ekpo ọkụ site arc na-echebe site na ikuku ikuku site na mmiri argon.

N'oge ịgbado ọkụ argon arc, ọnọdụ ndị ikwu nke ọkụ ọkụ, metal filler na weldment ka egosiri na foto dị n'okpuru: ogologo arc na-abụkarị 1 ~ 1.5 ugboro dayameta nke tungsten electrode.Mgbe ịgbado ọkụ ahụ kwụsịrị, a na-ebu ụzọ wepụ ihe mkpuchi ahụ site na ọdọ mmiri a wụrụ awụ (a na-agbakwunye ígwè na-ekpuchi ya dị ka ọkpụrụkpụ nke weldment), na njedebe na-ekpo ọkụ ka kwesịrị ịnọ n'okpuru nchebe nke argon eruba iji gbochie oxidation ya. .

1. Ọwa ọkụ (ọwa)

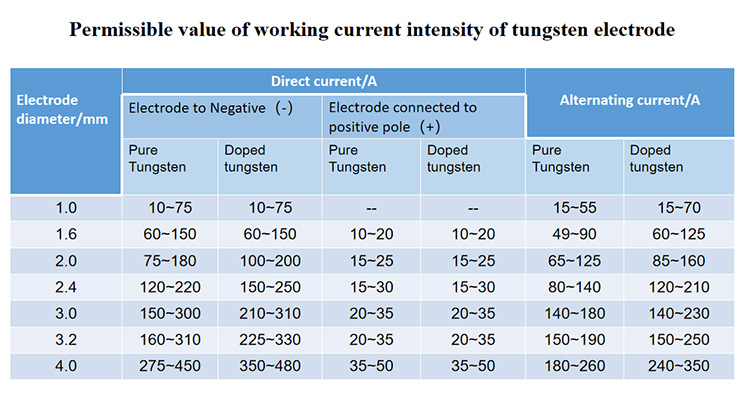

Na mgbakwunye na ịmachi tungsten electrode na ịnapụta ịgbado ọkụ ugbu a, argon tungsten arc ịgbado ọkụ ọkụ (nke a makwaara dị ka ọwa ịgbado ọkụ) kwesịrị ịgbasa gas mkpuchi.Egbe ịgbado ọkụ dị elu dị ugbu a kwesịrị iji egbe ịgbado ọkụ na-ajụ mmiri maka ịgbado ọkụ ogologo oge.Ya mere, ojiji na nchedo ziri ezi nke ọkụ ịgbado ọkụ dị ezigbo mkpa.Tungsten electrode ibu ikike ugbu a (A) ka egosiri na tebụl dị n'okpuru.

2. Ụzọ gas

Ụzọ gas bụ nke argon cylinder nrụgide na-ebelata valvụ, mita eruba, eriri na valvụ gas electromagnetic (n'ime igwe ịgbado ọkụ).A na-eji valvụ na-ebelata nrụgide iji belata nrụgide ma dozie nrụgide nke gas nchebe.A na-eji igwe na-agba ọsọ na-emezigharị ma na-edozi mgbaba gas na-echebe.Igwe ịgbado ọkụ nke Argon arc na-ejikarị ihe eji eme ihe nbibi, nke dị mma na ntụkwasị obi iji.

N'oge ịgbado ọkụ argon arc, ihe achọrọ maka ịdị ọcha nke gas argon bụ na chromium-nickel igwe anaghị agba nchara kwesịrị ịbụ ≥99.7%, na refractory metal kwesịrị ịbụ ≥99.98%.

(1) Argon bụ gas inert, ọ dịghịkwa mfe imeghachi omume na ihe ndị ọzọ ígwè na gas.Ọzọkwa, n'ihi mmetụta dị jụụ nke ikuku ikuku, mpaghara ikpo ọkụ na-emetụta okpomọkụ nke weld dị ntakịrị na nrụrụ nke weldment dị ntakịrị.Ọ bụ gas nchebe kachasị mma maka ịgbado ọkụ argon tungsten arc.

(2) A na-eji Argon eme ihe n'ụzọ dị irè iji chebe ọdọ mmiri a wụrụ awụ, gbochie ikuku site na imebi ọdọ mmiri a wụrụ awụ ma mee ka oxidation n'oge usoro ịgbado ọkụ, ma n'otu oge ahụ na-ekewapụ ikuku na mpaghara weld, nke mere na mpaghara weld bụ. echebe na ịgbado ọkụ arụmọrụ na-mma.

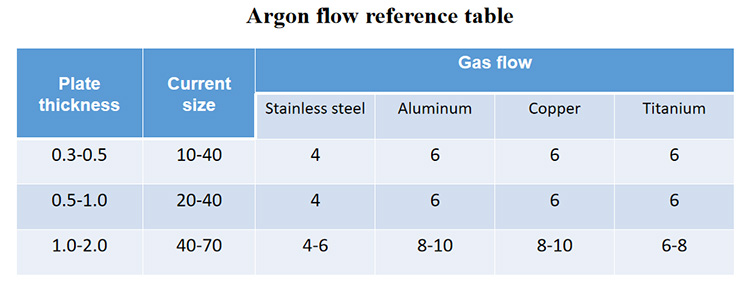

(3) A na-ekpebi usoro ngbanwe dị ka ihe igwe a ga-eji na-agbanye, nha nke ugbu a, na usoro ịgbado ọkụ: nke ukwuu ugbu a, ka gas na-echebe ka ukwuu.Maka ihe ndị na-arụ ọrụ na-arụ ọrụ, a ga-eme ka gas nchebe dị ike iji mee ka ọnụ ọgụgụ na-asọ asọ.

3. Ụdị nkọwapụta

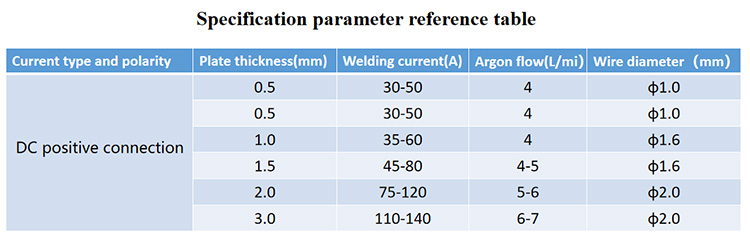

The ọkọlọtọ parameters nke argon tungsten arc ịgbado ọkụ tumadi gụnyere ugbu a, voltaji, ịgbado ọkụ ọsọ, na argon gas eruba, na ụkpụrụ ha metụtara ụdị ihe a ga-welded, efere efere na nkwonkwo ụdị.

Akụkụ ndị fọdụrụ dị ka ogologo nke tungsten electrode na-apụta site na nozzle bụ n'ozuzu 1-2 ugboro dayameta nke tungsten electrode, anya n'etiti tungsten electrode na weldment (ogologo arc) bụ n'ozuzu 1.5 ugboro dayameta nke tungsten. electrode, na size nke nozulu kpebisiri ike mgbe ịgbado ọkụ ugbu a bara uru.Họrọ ọzọ.

General igwe anaghị agba nchara argon arc ịgbado ọkụ nkọwa bụ dị ka ndị a:

4. Nhicha tupu ịgbado ọkụ

Tungsten argon arc ịgbado ọkụ na-enwe mmetụta nke ukwuu na mmetọ nke weldment na filler metal elu, ya mere a ga-ewepụ griiz, mkpuchi, mmanu na oxide film n'elu nke weldment tupu ịgbado ọkụ.

5. Teknụzụ nchekwa

Ndị na-arụ ọrụ ịgbado ọkụ argon tungsten arc ga-eyi ihe mkpuchi isi, uwe aka, uwe ọrụ, na akpụkpọ ụkwụ ọrụ iji zere ọkụ ọkụ ultraviolet na infrared na arc.Igwe ịgbado ọkụ Steyr tungsten argon arc nwere ihe mmalite arc na-adị elu.Ọ bụ ezie na ọkụ eletrik dị elu nke dị elu nke dị ala agaghị eme ka onye ọrụ ahụ maa jijiji, mgbe arụ ọrụ mkpuchi adịghị mma, ọkụ eletrik dị elu ga-agba akpụkpọ anụ nke onye ọrụ ahụ ọkụ , ọ na-esikwa ike ịgwọ ọrịa, ya mere, ọrụ mkpuchi ahụ. A ga-enyocharịrị aka ịgbado ọkụ ugboro ugboro.N'oge ịgbado ọkụ argon tungsten arc, ikuku ikuku na mpaghara ịgbado ọkụ kwesịrị ịkwalite.

Rịba ama: Ihe bụ isi bụ ịbụ onye ọkachamara na nka.Ọkpụrụkpụ nke osisi ahụ, oge ịpị, na nke ugbu a bụ ihe niile metụtara ya, ha kwesịrị ịkwado ibe ha.

Mgbe ị na-agbado ọkụ, atụla ebe agịga ahụ n'ebe ịgbado ọkụ na mmalite, ma tie ya efu ka ọ pụta ìhè n'ime ọkpọkọ, nke mere na ịgbado ọkụ ahụ agaghị agbawa ma ọ dịghị ntụpọ ojii.Sekọnd ole na ole, n'ụzọ dị otú a, a na-echebe igwe anaghị agba nchara site na argon gas n'oge oyi, n'ihi ya, ọ gaghị adị oji, na ọbụna mmiri ịsa ahụ na mpempe akwụkwọ na-egbuke egbuke na-echekwa.Enwere ike iji nke a naanị maka ịgbado ọkụ ntụpọ.Ọ bụrụ na ị dọkpụrụ ịgbado ọkụ n'ebe dị anya, ọ nweghị ụzọ.Osisi ahụ ga-agbanwerịrị agba.Ị ga-echere maka polishing na ihicha.

Oge nzipu: Mee-16-2023