Gịnị bụflux-coreed arc ịgbado ọkụ?

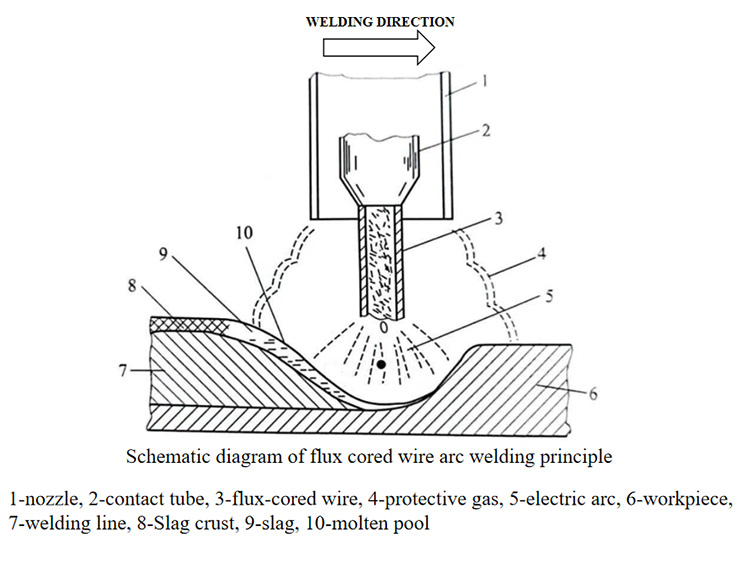

Flux-cored waya arc ịgbado ọkụ bụ usoro ịgbado ọkụ nke na-eji arc n'etiti flux-cored waya na workpiece na-ekpo ọkụ, na aha Bekee bụ nnọọ FCAW.N'okpuru omume nke aak okpomọkụ, ịgbado ọkụ waya metal na workpiece na-jikọrọ site agbaze, akpụ a weld ọdọ mmiri, aak n'ihu mgbe crystallization nke weld ọdọ mmiri ọdụ.

Kedu ihe bụ waya nwere eriri flux?Gịnị bụ àgwà nke katrij?

Waya ịgbado ọkụ Flux-cored bụ ụdị waya ịgbado ọkụ nke a na-eme site n'ịtụgharị eriri nchara nchara n'ime ọkpọkọ nchara ma ọ bụ ọkpọkọ nchara nwere ụdị pụrụ iche, na-ejupụta ọkpọkọ ahụ na akụkụ ụfọdụ nke ntụ ntụ, na eserese.Ngwakọta nke isi ntụ ntụ yiri nke mkpuchi electrode, bụ nke kachasị nke arc stabilizing agent, slag forming agent, gas forming agent, alloying agent, deoxidizing agent, wdg.

Gịnị bụ ọrụ nke flux na flux-coreed waya?

Ọrụ nke flux yiri nke mkpuchi electrode, ma enwere ụdị ndị a.

① Nchekwa mmetụta nke ụfọdụ components na ịgbado ọkụ flux decomposition, ụfọdụ agbaze!Mwepu nke ịgbado ọkụ na-ahapụ gas, nke na-enye ụfọdụ ma ọ bụ ọtụtụ nchebe.Mgbọrọgwụ nke a wụrụ awụ na-emepụta slag a wụrụ awụ, nke na-ekpuchi elu nke mmiri mmiri na ọdọ mmiri a wụrụ awụ, igwe mmiri ahụ na-echebe ya.

② Arc stabilizer na arc stabilizer katrij nwere ike mee ka arc kwụsie ike ma belata ọnụego spatter.

③ Alloying action Ụfọdụ n'ime ihe alloy dị na isi nwere ike tinye weld ahụ.

④ Deoxidation alloy ọcha nke slag nwere ike meghachi omume na mmiri mmiri ọla.Meziwanye ihe mejupụtara nke weld metal, meziwanye akụrụngwa ya.

Tụkwasị na nke ahụ, slag ahụ kpuchiri ekpuchi nwekwara ike ibelata ọnụego jụrụ oyi nke ọdọ mmiri a wụrụ awụ, na-agbatị oge ịdị adị nke ọdọ mmiri a wụrụ awụ, nke bara uru iji belata ọdịnaya nke gas na-emerụ ahụ na weld ma gbochie porosity.

Kedu ụdị ịgbado ọkụ nke flux cored arc dị?

Enwere ụdị abụọ nke flux cored wire arc welding (FCAW-G) yana ịgbado ọkụ nke onwe (FCAW-S), dabere ma ejiri gas mkpuchi mpụga ma ọ bụ na ejighi ya.

Igwe ikuku na-ekpuchi ikuku nke waya flux na-ejikarị carbon dioxide ma ọ bụ carbon dioxide gbakwunyere argon dị ka gas na-echebe, na mmiri na waya nwere obere ihe na-ekpo ọkụ.Usoro a yiri ịgbado ọkụ n'ozuzu gas na-echebe.Ịgbado ọkụ na-echebe onwe ya adịghị mkpa gas nchebe mpụga.Enwere ọnụ ọgụgụ dị ukwuu nke gasifier na ntụgharị, na gas na slag mebiri site na gasifier na-eji maka nchebe.

Kedu uru ọ dị na ịgbado ọkụ na-eme ka flux-cored arc?

Ịgbado ọkụ na-eme ka arc agbụ nwere uru ndị a.

(1) Nnukwu ịgbado ọkụ arụpụta ọrụ dị elu na-agbaze arụmọrụ (ruo 85% ~ 90%), ọsọ agbaze ngwa ngwa;Maka ịgbado ọkụ dị larịị, mkpuchi mkpuchi bụ ugboro 1.5 nke ịgbado ọkụ akwụkwọ ntuziaka, yana maka ọnọdụ ịgbado ọkụ ndị ọzọ, ọ bụ ugboro 3-5 nke ịgbado ọkụ akwụkwọ ntuziaka.

② Obere splash, weld na-akpụ ezigbo ọgwụ isi agbakwunyere arc stabilizer, yabụ nkwụsi ike arc, obere splash, ezigbo weld na-akpụ.N'ihi na ọdọ mmiri a wụrụ awụ jupụtara na slag a wụrụ awụ, ọdịdị elu weld dị mma nke ukwuu karịa nke ịgbado ọkụ carbon dioxide.

(3) Ogo ịgbado ọkụ dị elu N'ihi nchekwa nke slag gas jikọtara ọnụ, ọ nwere ike igbochi gas na-emerụ ahụ nke ọma ịbanye na mpaghara ịgbado ọkụ.Tụkwasị na nke ahụ, ịdị adị nke ọdọ mmiri a wụrụ awụ dị ogologo, nke na-eme ka mmiri ozuzo gas, ya mere weld nwere obere ọdịnaya hydrogen na ezigbo nkwụsị porosity.

(4) Mgbanwe siri ike dị naanị mkpa iji dozie nhazi nke eriri waya na-eme ka ọ dị mma, ọ nwere ike izute ihe ndị a chọrọ n'ụdị dị iche iche na weld mejupụtara.

Kedu ihe ọghọm dị na ịgbado ọkụ nke flux-coreed arc?

Mmejọ nke ịgbado ọkụ nke flux-coreed arc bụ ndị a.

N'iji ya tụnyere ịgbado ọkụ na-ekpuchi gas, ọnụahịa nke waya ịgbado ọkụ dị elu na usoro mmepụta ihe dị mgbagwoju anya.

② Nri nri waya siri ike, ọ dị mkpa iji igwe na-enye nri waya nke enwere ike ịhazigharị nrụgide nke ọma.

③ The cartridge dị mfe ịmịkọrọ mmiri mmiri, ya mere ọ dị mkpa idobe waya ịgbado ọkụ.

④ Slag mwepụ dị mkpa mgbe ịgbado ọkụ.

⑤ A na-emepụtakwu anwụrụ ọkụ na gas na-emerụ ahụ na usoro ịgbado ọkụ, ya mere ekwesịrị ime ka ikuku ikuku sie ike.

Kedu gas nchebe ka a na-ejikarị na mgbado ọkụ nke nwere eriri?Kedu ihe njirimara nke ọ bụla?

Flux cored waya arc ịgbado ọkụ na-ejikarị carbon dioxide gas ma ọ bụ carbon dioxide na argon gas dị ka gas na-echebe.Ọ dị mkpa ịhọrọ ụdị gas dị ka waya flux-cored ejiri mee ihe.

Argon dị mfe ionized, n'ihi ya, ọ dị mfe iji nweta mgbanwe ejection na argon arc.Mgbe ọdịnaya argon nke ngwakọta gas na-erughị 75%, ịgbado ọkụ na-agbado waya nwere ike nweta mgbanwe ụgbọ elu kwụsiri ike.Site na mbelata nke ọdịnaya argon, omimi ntinye na-abawanye, mana nkwụsi ike nke arc na-ebelata na ọnụọgụ spatter na-abawanye.Ya mere, ngwakọta gas kacha mma bụ 75% Ar + 25% CO2.Na mgbakwunye, Ar + 2% O2 nwekwara ike iji maka ngwakọta gas.

Mgbe a na-ahọrọ gas CO2 dị ọcha, ọ ga-agbaze n'okpuru ọrụ nke arc okpomọkụ ma mepụta ọnụ ọgụgụ dị ukwuu nke ikuku oxygen, nke ga-eme ka manganese, silicon na ihe ndị ọzọ dị na ọdọ mmiri a wụrụ awụ, na-eduga na ọkụ nke ihe ndị na-emepụta ihe.Ya mere, ekwesịrị iji waya ịgbado ọkụ nwere nnukwu manganese na silicon.

Oge nzipu: Mee-09-2023