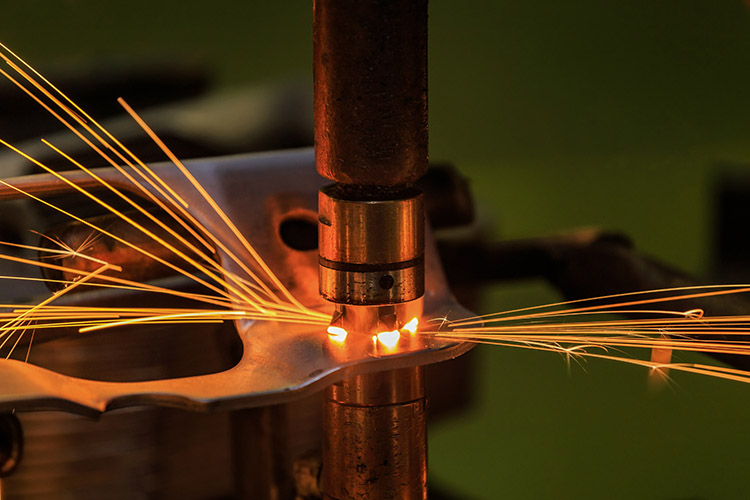

Ntụpọ ịgbado ọkụ bụ a iguzogide ịgbado ọkụ usoro na nke weldment na-agbakọta n'ime a n'apata nkwonkwo na-enwe n'etiti abụọ electrodes, na isi metal gbazere site na-eguzogide okpomọkụ na-etolite a solder nkwonkwo.

A na-ejikarị welding ntụpọ eme ihe n'akụkụ ndị a:

1. Lap nkwonkwo nke mpempe akwụkwọ stamping akụkụ, dị ka ụgbọ ala ụgbọ ala, ụgbọ ala, azụ ọnụ ọgụgụ ihuenyo nke ihe ubi, wdg.

2. Efere dị larịị na akụkụ akụkụ ígwè na akụkụ akpụkpọ anụ, dị ka mgbidi n'akụkụ na uko ụlọ nke ụgbọ ala, akụkụ nke ụgbọala na-adọkpụ, ikpokọta ihe ọkụkụ, wdg.

3. Ihuenyo, oghere oghere na obe obe, wdg.

Cime ihe ike

N'oge ịgbado ọkụ ntụpọ, weldment na-etolite nkwonkwo ụkwụ ma na-apịa ya n'etiti electrodes abụọ.Isi njirimara ya bụ ndị a:

1. Oge ikpo ọkụ nke mpaghara njikọ dị mkpụmkpụ n'oge ịgbado ọkụ, na ịgbado ọkụ na-agba ngwa ngwa.

2. Ịgbado ọkụ ntụpọ na-eri naanị ike eletrik, ọ dịghịkwa achọ ihe ndochi ma ọ bụ flux, gas, wdg.

3. The àgwà nke ntụpọ ịgbado ọkụ bụ tumadi na-ekwe nkwa site ntụpọ ịgbado ọkụ igwe.Ọrụ ahụ dị mfe, ogo nke mechanization na akpaaka dị elu, na mmepụta dị elu.

4. Ịrụ ọrụ dị ala na ọnọdụ ọrụ dị mma.

5. Ebe ọ bụ na a na-emecha ike ịgbado ọkụ n'ime obere oge, a na-achọ nnukwu ugbu a na nrụgide, ya mere njikwa mmemme nke usoro ahụ dị mgbagwoju anya karị, igwe ịgbado ọkụ nwere nnukwu ikike, na ọnụahịa nke akụrụngwa dị ntakịrị. elu.

6.Ọ siri ike na-eduzi ule na-adịghị emebi emebi na nkwonkwo solder.

Usoro ọrụ

N'elu nke workpiece kwesịrị kpochara tupu ịgbado ọkụ.Ụzọ ihicha a na-ejikarị eme ihe bụ ịsachapụ ihe, ya bụ, ịtụkọta sulfuric acid na-ekpo ọkụ na ntinye nke 10%, wee sachaa na mmiri ọkụ.Usoro ịgbado ọkụ a kapịrị ọnụ bụ nke a:

(1) Ziga workpiece nkwonkwo n'etiti elu na ala electrodes nke ntụpọ ịgbado ọkụ igwe na mwekota ya;

(2) electrification, nke mere na kọntaktị na-ebupụta nke abụọ workpieces na-ekpo ọkụ na akụkụ gbazee na-etolite a nugget;

(3) Debe nrụgide ahụ mgbe ebipụchara ike ahụ, nke mere na nugget ahụ dị jụụ ma sie ike n'okpuru nrụgide iji mepụta nkwonkwo solder;

(4) Wepu nrụgide ma wepụ workpiece.

Ihe na-emetụta

Isi ihe na-emetụta àgwà ịgbado ọkụ bụ ịgbado ọkụ ugbu a na oge ume ike, nrụgide electrode na shunt, wdg.

1. Welding ugbu a na ume oge

Dị ka nha nke ịgbado ọkụ ugbu a na ogologo oge ike ume, ntụpọ ịgbado ọkụ nwere ike kewaa abụọ ụdị: ike nkọwapụta na nro nkọwapụta.Nkọwapụta nke na-agafe nnukwu ugbu a n'ime obere oge ka a na-akpọ nkọwa siri ike.Ọ nwere uru nke nrụpụta dị elu, ogologo ndụ electrode, na obere nrụrụ nke weldment.Ọ dabara maka ịgbado ọla na mma thermal conductivity.Nkọwa nke na-agafe obere ugbu a maka ogologo oge ka a na-akpọ nkọwa dị nro, nke nwere obere arụpụtaghị ihe ma dị mma maka ịgbado ígwè na-emekarị ka ọ sie ike.

2. Electrode mgbali

N'oge ịgbado ọkụ ntụpọ, nrụgide electrode na-etinye na weldment ka a na-akpọ nrụgide electrode.Ekwesịrị ịhọrọ nrụgide electrode nke ọma.Mgbe nrụgide dị elu, porosity shrinkage na oghere shrinkage nke nwere ike ime mgbe ngwut siri ike nwere ike ikpochapụ, ma njikọ njikọ na njupụta ugbu a na-ebelata, na-akpata ezughị ezu kpo oku nke weldment na mbelata na dayameta nke nugget solder nkwonkwo.Ike nke nkwonkwo solder na-ebelata.Enwere ike ịhọrọ oke nrụgide electrode dị ka ihe ndị a:

(1) Ihe nke weldment.Nke dị elu elu ike okpomọkụ nke ihe onwunwe.Nke ka ukwuu nke nrụgide electrode chọrọ.Ya mere, mgbe ịgbado ọkụ igwe anaghị agba nchara na okpomọkụ na-eguzogide ígwè, electrode mgbali kwesịrị ịdị elu karịa nke obere carbon ígwè.

(2) welding parameters.Ka nkọwapụta weld siri sie ike, ka nrụgide electrode na-abawanye.

3. shunt

N'oge ịgbado ọkụ ntụpọ, nke ugbu a na-eru site na mpụga sekit isi ịgbado ọkụ ka a na-akpọ shunt.Shunt na-ebelata ugbu a na-agafe na mpaghara ịgbado ọkụ, na-eme ka ikpo ọkụ na-ezughị ezu, na-eme ka mbelata dị ukwuu na ike nke nkwonkwo solder na-emetụta àgwà ịgbado ọkụ.Ihe ndị na-emetụta ogo ntugharị ahụ gụnyere akụkụ ndị a:

(1) The ọkpụrụkpụ nke weldment na spacing nke solder nkwonkwo.Ka ebe dị n'etiti nkwonkwo solder na-abawanye, nkwụsị nke shunt na-abawanye na ogo nke shunt na-ebelata.Mgbe anabatara ntụpọ ntụpọ nke 30-50mm, shunt ugbu a na-akpata 25% -40% nke ngụkọta ugbu a, yana ka ọkpụrụkpụ nke weldment na-ebelata, ogo nke shunt na-ebelatakwa.

(2) Ọnọdụ elu nke weldment.Mgbe enwere oxides ma ọ bụ unyi n'elu welding, nguzogide kọntaktị n'etiti welding abụọ na-abawanye, na ugbu a site na ebe ịgbado ọkụ na-ebelata, ya bụ, ogo nke shunt na-abawanye.Enwere ike ịchịkọta ihe eji arụ ọrụ, sandblasted ma ọ bụ na-egbu maramara.

Akpachara anya maka nchekwa

(1) Mgbanwe ụkwụ nke igwe ịgbado ọkụ kwesịrị inwe mkpuchi nchebe siri ike iji gbochie ịgbalite mberede.

(2) Ebe a na-arụ ọrụ ga-enwe ihe mgbagwoju anya iji gbochie mwusa ọkụ na-arụ ọrụ.

(3) Ndị na-agbado ọkụ kwesịrị iyi ugegbe nchebe dị larịị mgbe ha na-agbado.

(4) Ebe a na-etinye igwe ịgbado ọkụ kwesịrị ka akpọọ nkụ, ma kpuchie ala ya na bọọdụ mgbochi skid.

(5) Mgbe ọrụ ịgbado ọkụ ahụ gasịrị, a ga-ebipụ ọkụ ọkụ, na mmiri na-ekpo ọkụ kwesịrị ịgbatị maka 10 sekọnd tupu emechi.Mgbe okpomọkụ dị ala, a ga-ewepụ mmiri a na-akwakọba n'ime mmiri iji gbochie oyi.

Oge nzipu: Jul-31-2023