-FLUX-

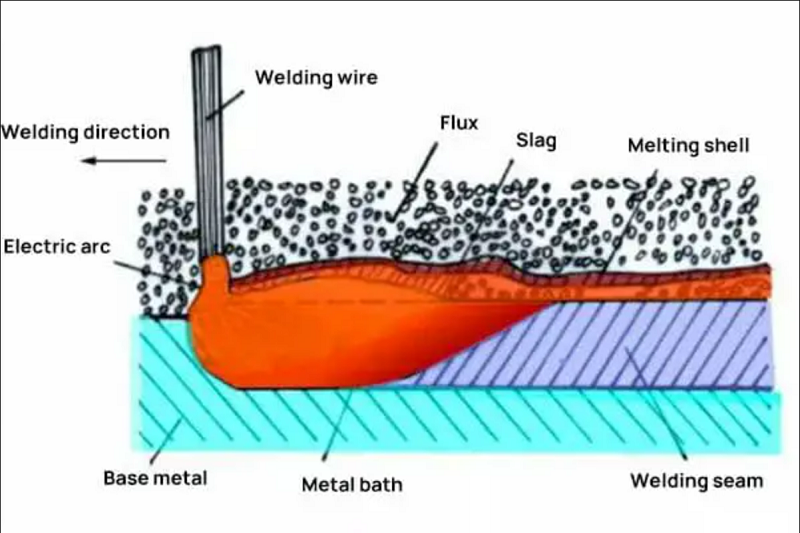

Fluxbụ ihe mgbado ọkụ granular.N'oge ịgbado ọkụ, enwere ike ịgbaze ya ka ọ bụrụ slag na gas, nke na-arụ ọrụ nchebe na nke ọla na ọdọ mmiri a wụrụ awụ.

Ihe mejupụtara

Flux mejupụtara marble, quartz, fluorite na ọla ndị ọzọ na titanium dioxide, cellulose na kemịkalụ ndị ọzọ.A na-eji Flux eme ihe maka ịgbado ọkụ n'ime mmiri na welding electroslag.Mgbe ejiri ya maka ịgbado ụdị ígwè ọ bụla na ọla ndị na-abụghị nke ferrous, ọ ga-abụrịrị ihe ezi uche dị na ya iji waya ịgbado ọkụ kwekọrọ na ya ka ọ wee nweta weld na-eju afọ.

Nhazi

Enwere ọtụtụ ụzọ nhazi ọkwa nke flux, dị ka ojiji, usoro nrụpụta, kemịkalụ kemịkalụ, ịgbado ọkụ na ihe ọla nke nhazi ahụ, mana dịkwa ka pH nke flux, nhazi ọkwa granularity flux.N'agbanyeghị ụdị usoro nhazi ọkwa, naanị na-egosipụta njirimara nke mgbanwe site na akụkụ ụfọdụ, ọ nweghị ike ịgụnye njirimara niile nke mgbanwe.Ụzọ nhazi ọkwa ndị a na-ejikarị bụ:

1. Mgbanwe na-anọpụ iche

Mgbanwe na-anọpụ iche na-ezo aka na mgbawa nke na-adịghị agbanwe nke ọma ihe mejupụtara kemịkalụ nke metal fused na ihe mejupụtara kemịkalụ nke waya ịgbado ọkụ mgbe ịgbado ọkụ.A na-eji mmiri na-anọpụ iche eme ihe maka ịgbado ọkụ multi-pass, karịsịa maka ịgbado ọkụ nke metal ntọala na ọkpụrụkpụ karịa 25mm. Neutral flux nwere àgwà ndị a:

a.Mgbanwe ahụ enweghị SiO2, MnO, FeO na oxides ndị ọzọ.

b.Flux enweghị mmetụta oxidation na weld metal n'ụzọ bụ isi.

c.Mgbe welding base metal na oké oxidation, pores na weld cracks ga-emepụta.

2. Mgbanwe na-arụ ọrụ

Mgbanwe na-arụ ọrụ na-ezo aka na mgbakwunye nke obere ego nke Mn, Si deoxidizer flux.Ọ nwere ike melite nguzogide porosity na mgbawa.Flux na-arụ ọrụ nwere njirimara ndị a:

a.N'ihi deoxidizer, Mn na Si na metal a wụrụ awụ ga-agbanwe site na voltaji arc.Mmụba nke Mn na Si ga-eme ka ike nke igwe a wụrụ awụ ma belata mmetụta siri ike.Ya mere, a ga-achịkwa arc voltaji mgbe ịgbado ọkụ multi-pass.

b.Mgbanwe na-arụ ọrụ nwere nguzogide porosity siri ike.

3. Alloy flux

Alloy flux gbakwunyere ihe ndị ọzọ alloy maka mgbanwe nke ihe ndị na-eme ka alloying, ọtụtụ n'ime ihe ndị na-emepụta ihe na-eme ka ọ bụrụ ihe na-eme ka ọ dị nro.Alloy flux bụ tumadi eji maka ịgbado ọkụ nke ala alloy ígwè na eyi na-eguzogide surfacing.

4. Na-agbaze agbaze

Mgbaze mgbaze bụ akụrụngwa nke mineral dị iche iche agwakọtara dabere na nha enyere, kpụ ọkụ n'ọnụ karịa ogo 1300, gbazee ma kpalie ya nke ọma, wee mee ka ọ dị mma na mmiri ka ọ bụrụ granulate.Mgbe ihicha, egweri, screening, nkwakọ ojiji.

A na-egosipụta akara mgbaze n'ime ụlọ site na "HJ".Nkeji nke mbụ na-egosi ọdịnaya nke MnO, nke abụọ na-egosi ọdịnaya nke SiO2 na CaF2, na nkeji nke atọ na-egosi ụdị dị iche iche nke otu ụdị mgbanwe.

5. Na-agbagharị agbagharị

A na-agwakọta ya dị ka ihe na-esi ísì ụtọ si dị, wee gbakwunye ihe nkedo (iko mmiri) maka ịgwakọta mmiri, wee granulation, ma zigara ya na ọkụ ọkụ na-ekpo ọkụ na-agwọ, ihicha, na n'ikpeazụ sintered ihe dị ka ogo 500.

Akara mmiri nke ụlọ sintered bụ “SJ” nọchiri anya ya, ọnụọgụ nke mbụ na-anọchi anya sistemụ slag, ọnụọgụ nke abụọ na nke atọ na-anọchi anya ụdị dị iche iche nke otu sistemụ slag.

Oge nzipu: Mee-04-2023