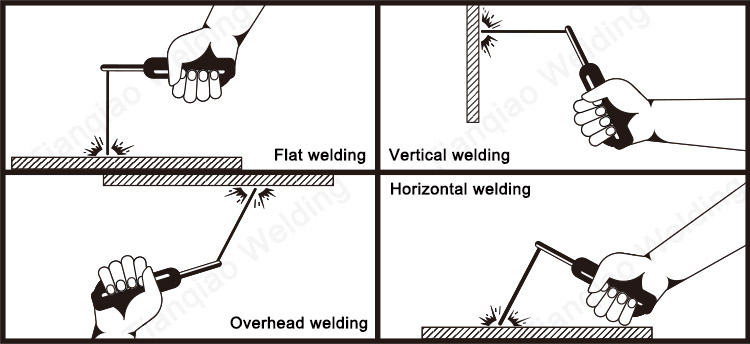

A na-ezo aka na ọnọdụ ịgbado ọkụ mgbe ịgbado ọkụ, ndị ikwu gbasara ohere ọnọdụ nke weld na welder.

Ọgụgụ 1. Tianqiao welding positon

Ọgụgụ 1. Tianqiao welding positon

Enwere ịgbado ọkụ dị larịị, ịgbado ọkụ kwụ ọtọ, ịgbado ọkụ kwụ ọtọ na ịgbado ọkụ n'elu.Flat ịgbado ọkụ na-ezo aka kehoraizin ịgbado ọkụ rụrụ site welder na-ehulata isi ya, n'ihi ya, ọ na-akpọ downhand ịgbado ọkụ;n'ihi na weld na T-ụdị njikọ, T-ụdị weldment na-na-etinyekarị na 45 ° na-etolite ịgbado ọkụ ọnọdụ nke ala ịgbado ọkụ onuete, nke a na-akpọ ịgbado ọkụ ụgbọ.Ịgbado ọkụ kwụ ọtọ na-ezo aka na ịgbado ọkụ kwụ ọtọ nke onye welder na-eme n'ihe dị ka ogo ogwe aka.Vetikal ịgbado ọkụ na-ezo aka ala-elu vetikal ịgbado ọkụ site welder.Ịgbado ọkụ n'elu na-ezo aka na ịgbado ọkụ kwụ ọtọ nke onye welder na-ele anya elu.Flat ịgbado ọkụ bụ ihe kacha mfe iji hụ na ịgbado ọkụ àgwà, kehoraizin ịgbado ọkụ bụ nke abụọ, vetikal ịgbado ọkụ bụ nke atọ, na n'elu ịgbado ọkụ bụ ihe kasị sie ike ịhụ na àgwà na kwesịrị izere dị ukwuu dị ka o kwere.

Ọgụgụ 2. Tianqiao ewepụghị ịgbado ọkụ

Ọgụgụ 2. Tianqiao ewepụghị ịgbado ọkụ

Mgbado ọkụ dị larịị

Njirimara ịgbado ọkụ nke flat welding:

1. Ngwongwo weld na-adabere n'ịdị arọ nke ya ka ọ gaa na ọdọ mmiri a wụrụ awụ.

2. Ụdị na ígwè nke ọdọ mmiri a wụrụ awụ dị mfe ijikwa ma na-achịkwa.

3. N'ihi na ịgbado ọkụ ọla na otu ọkpụrụkpụ, na ịgbado ọkụ ugbu a na larịị ịgbado ọkụ ọnọdụ bụ ibu karịa na ndị ọzọ ịgbado ọkụ ọnọdụ, na mmepụta arụmọrụ dị elu.

4. Slag na ọdọ mmiri a wụrụ awụ na-adịkarị mfe ịgwakọta, karịsịa mgbe ị na-agbado welds flat fillet, slag dị mfe iduga ma na-etolite nsonye slag.

* Ọ dịghị mfe ịmata ọdịiche nke slag nke mkpara ịgbado acid na ọdọ mmiri a wụrụ awụ;abụọ nke alkaline ịgbado ọkụ mkpara bụ dịtụ doro anya;ọkọlọtọ HG20581 na-ekwu n'ụzọ doro anya na enweghị ike iji mkpanaka ịgbado ọkụ acid na arịa Klas II na III.

5. Mpempe ịgbado ọkụ na-ezighi ezi na arụmọrụ nwere ike ibute ntụpọ dị ka weld bead, undercut, and welding deformation.

6. Mgbe n'azụ akụkụ nke otu-akụkụ ịgbado ọkụ na-free kpụrụ, akpa weld na-adịkarị mfe na-erughị eru penetration usoro na ogbenye azụ ịkpụzi.

Ebe ịgbado ọkụ nke flat ịgbado ọkụ:

1. Dị ka ọkpụrụkpụ nke efere ahụ, a pụrụ iji nnukwu electrode dayameta na nnukwu ịgbado ọkụ ugbu a.

2. Mgbe ịgbado ọkụ, mkpanaka ịgbado ọkụ na welding na-etolite akụkụ nke 60 ~ 80 Celsius, na nkewa nke slag na mmiri mmiri metal na-achịkwa iji gbochie slag ahụ ka ọ pụta ìhè n'ihu.

3. Mgbe efere ọkpụrụkpụ bụ ihe na-erughị ma ọ bụ hà 6mm, butt flat ịgbado ọkụ n'ozuzu nwere ụdị m uzo, na n'ihu ịgbado ọkụ onuete kwesịrị mkpụmkpụ-akụrụ ịgbado ọkụ na a φ3.2 ~ 4 electrode, na penetration omimi nwere ike. iru 2/3 nke ọkpụrụkpụ efere;tupu azụ na-akara, Ọ dịghị mkpa ka ihicha mgbọrọgwụ (ma e wezụga n'ihi na ihe owuwu dị mkpa), ma slag ga-kpochara na ugbu a nwere ike ibu ibu.

4. Ọ bụrụ na e nwere edoghị agwakọta nke slag na wụrụ awụ ọdọ mmiri metal na butt flat ịgbado ọkụ, na arc nwere ike elongated, na electrode nwere ike tilted n'ihu, na a wụrụ awụ slag nwere ike kpaliri n'azụ nke wụrụ ọdọ mmiri iji gbochie slag nsonye.

5. Mgbe ịgbado ọkụ horizontally chọrọ welds, upslope ịgbado ọkụ kwesịrị iji gbochie slag nsonye na wụrụ awụ ọdọ mmiri si na-aga n'ihu iji zere slag nsonye.

6. Mgbe ị na-eji multi-layer na multi-pass welding, ṅaa ntị na ọnụ ọgụgụ nke ịgbado ọkụ na usoro ịgbado ọkụ, na oyi akwa ọ bụla ekwesịghị gafere 4 ~ 5mm.

7. N'ihi na ewepụghị-n'akuku welded nkwonkwo nke T ụdị, nkuku nkwonkwo, na overlap nkwonkwo, ma ọ bụrụ na ọkpụrụkpụ nke abụọ efere dị iche iche, n'akuku nke ịgbado ọkụ mkpara ga-gbanwee na-deflect na arc n'otu akụkụ nke oké efere. nke mere na efere abụọ ahụ na-ekpo ọkụ nke ọma.

8. Nhọrọ ziri ezi nke usoro mbupu

(1) Mgbe ịgbado ọkụ ọkpụrụkpụ bụ ihe na-erughị ma ọ bụ hà 6mm, ụdị m uzo butt flat ịgbado ọkụ.Mgbe a na-anabata ịgbado ọkụ n'akụkụ abụọ, oghere ịgbado ọkụ n'ihu na-enweta ahịrị kwụ ọtọ, nke na-eji nwayọ nwayọ;azụ ịgbado ọkụ onuete nakwa adopts a ogologo ahịrị, na ịgbado ọkụ ugbu a bụ ubé ibu., Ọsọ ọsọ.

(2) Mgbe ọkpụrụkpụ nke efere bụ ≤6mm, mgbe na-emeghe ndị ọzọ ụdị grooves, multi-layer ịgbado ọkụ ma ọ bụ multi-layer multi-pass welding nwere ike iji.Akpa oyi akwa nke ala ịgbado ọkụ kwesịrị iji obere ugbu a electrode, obere ọkọlọtọ ugbu a, ogologo ahịrị ma ọ bụ sawtooth.Ọdịdị njem mmanya ịgbado ọkụ.Maka ndochi ịgbado ọkụ oyi akwa, enwere ike ịhọrọ electrode dayameta buru ibu na ịgbado ọkụ dị mkpụmkpụ nwere ugbu a ịgbado ọkụ ka ukwuu.

(3) Mgbe nha nke ụkwụ nke ịgbado ọkụ fillet dị larịị nke T-njikọ na-erughị 6mm, enwere ike iji ịgbado ọkụ otu oyi akwa, enwere ike iji usoro mbufe nke nwere akara, mgbanaka oblique ma ọ bụ zigzag;mgbe nha ụkwụ dị ukwuu, a ga-eji ịgbado ọkụ multi-layer ma ọ bụ multi-layer welding.Multi-pass ịgbado ọkụ, ala ịgbado ọkụ nakweere linear warara ụzọ njem, na ndochi oyi akwa nwere ike họrọ oblique sawtooth ma ọ bụ oblique okirikiri warara njem.

(4) N'ozuzu, multi-layer na multi-pass ịgbado ọkụ kwesịrị welded site ogologo ahịrị iga usoro.

Dị nwayọọ ígwè electrodes adabara ewepụghị ịgbado ọkụ bụAWS E6013, AWS E6010, AWS E6011, AWS E7018.

Ọgụgụ 3. Tianqiao vetikal ịgbado ọkụ

Ọgụgụ 3. Tianqiao vetikal ịgbado ọkụ

Mgbado ọkụ kwụ ọtọ

Njirimara ịgbado ọkụ nke vetikal ịgbado ọkụ:

1. Ngwongwo ọdọ mmiri a wụrụ awụ na slag a wụrụ awụ dara n'ihi ịdị arọ nke aka ha ma dị mfe ikewapụ.

2. Mgbe okpomọkụ nke ọdọ mmiri a wụrụ awụ dị oke elu, igwe a wụrụ awụ na-adị mfe ịkụda ala iji mepụta ntụpọ dị ka weld bead, undercut, slag inclusion, wdg, na weld bụ enweghị isi.

3. Mgbọrọgwụ nke T-njikọ weld dị mfe ịmepụta ntinye ezughị ezu.

4. Ogo nke ntinye dị mfe nghọta.

5. Welding arụpụtaghị ihe dị ala karịa ewepụghị ịgbado ọkụ.

Isi ihe nke ịgbado ọkụ kwụ ọtọ:

1. Jikwaa n'akuku mkpanaka ịgbado ọkụ ziri ezi;

2. Na mmepụta, a na-ejikarị ịgbado ọkụ kwụ ọtọ, na ịgbado ọkụ kwụ ọtọ na-achọ mkpado ịgbado ọkụ pụrụ iche iji hụ na ịdị mma nke weld.The ịgbado ọkụ ugbu a maka vetikal elu ịgbado ọkụ bụ 10 ~ 15% nta karịa nke ewepụghị ịgbado ọkụ, na a nta electrode dayameta (<φ4mm) kwesịrị họrọ.

3. Jiri obere ịgbado ọkụ ka ọ dị mkpụmkpụ site na droplet ruo ọdọ mmiri a wụrụ awụ.

4. Jiri usoro mbupu ziri ezi.

(1) T-groove butt nkwonkwo (nke a na-ejikarị eme efere dị mkpa) mgbe a na-eme ịgbado ọkụ kwụ ọtọ, linear, zigzag, welding welding na-ejikarị eme ihe, na ogologo arc agaghị agafe 6mm.

(2) Mgbe ị na-emeghe ụdị ndị ọzọ nke groove butt vetikal ịgbado ọkụ, nke mbụ oyi akwa weld na-emekarị welded site gbajiri agbaji, crescent ekara na triangular ekara warara ịgbado ọkụ na obere siwing.Mgbe e mesịrị, enwere ike iji oyi akwa ọ bụla mee ihe maka mgbanaka ọnwa ma ọ bụ zigzag.

(3) N'oge vetikal ịgbado ọkụ nke T-ekara nkwonkwo, na ịgbado ọkụ mkpara kwesịrị inwe ihe kwesịrị ekwesị obibi oge na abụọ na n'elu nkuku nke ịgbado ọkụ onuete, na siwing amplitude nke ịgbado ọkụ mkpanaka ekwesịghị ịbụ ukwuu karịa obosara nke ịgbado ọkụ. onuete.Ọrụ nke mkpanaka ịgbado ọkụ yiri nke ịgbado ọkụ ndị ọzọ kwụ ọtọ na grooves.

(4) Mgbe ị na-agbado oyi akwa mkpuchi, a na-ekpebi ọdịdị elu nke weld site na usoro njem.Enwere ike iji ibe nke yiri nke crescent maka ịgbado oghere nke nwere oke chọrọ;Enwere ike iji eriri zigzag maka ebe dị larịị (ụdị concave dị n'etiti jikọtara ya na oge nkwụsịtụ).

Dị nwayọọ ígwè electrodes adabara vetikal ịgbado ọkụ bụAWS E6013, AWS E6010, AWS E6011, AWS E7018, karịsịaE6011dabara adaba maka ịgbado ọkụ kwụ ọtọ elu-ala.

Ọgụgụ 4. Tianqiao ịgbado ọkụ n'elu

ịgbado ọkụ n'elu

Njirimara ịgbado ọkụ nke ịgbado ọkụ n'elu:

1. Igwe a wụrụ awụ na-ada n'ihi ike ndọda, na ọdịdị na nha nke ọdọ mmiri a wụrụ awụ ekwesịghị ịchịkwa.

2. O siri ike ibufe warara, na elu nke welded adịghị mma maka ịgbado ọkụ.

3. Ọdịiche dị ka ntinye slag, ntinye ezughị ezu, bead weld na nhazi weld na-adịghị mma dị mfe ịpụta.

4. Ígwè ahụ a wụrụ awụ na-awụsa wee gbasaa, nke nwere ike ịkpata ihe mberede ọkụ ngwa ngwa.

5. Ịrụ ọrụ nke ịgbado ọkụ n'elu dị ala karịa nke ọnọdụ ndị ọzọ.

Ebe ịgbado ọkụ n'elu:

1. N'elu welding nke butt welds.Mgbe ọkpụrụkpụ nke weldment bụ ihe na-erughị ma ọ bụ hà 4mm, na-eji ụdị m grooves na-eji φ3.2mm ịgbado ọkụ mkpara na agafeghị oke ịgbado ọkụ ugbu a;mgbe ọkpụrụkpụ ịgbado ọkụ ka ukwuu ma ọ bụ hà 5mm, multi-layer na multi-pass ịgbado ọkụ kwesịrị iji.

2. The onuete ịgbado ọkụ nke T-ekara nkwonkwo bụ n'elu ịgbado ọkụ.Mgbe ụkwụ ịgbado ọkụ na-erughị 8mm, a ga-eji otu-layer ịgbado ọkụ, na mgbe ịgbado ọkụ ụkwụ karịrị 8mm, multi-layer na multi-pass ịgbado ọkụ kwesịrị iji.

3. Dị ka ọnọdụ akọwapụtara, were usoro mbupu ziri ezi:

(1) Mgbe nha nke ụkwụ ịgbado ọkụ dị ntakịrị, a na-eji ụdị nkwụghachi azụ nke ahịrị ma ọ bụ ahịrị iji mechaa ịgbado ọkụ nke otu oyi akwa;mgbe nha nke ụkwụ ịgbado ọkụ dị ukwuu, enwere ike iji ịgbado ọkụ multi-layer ma ọ bụ multi-layer multi-pass welding, na nke mbụ oyi akwa kwesịrị iji kwụ n'ahịrị njem, ndị ọzọ n'ígwé nwere ike họrọ oblique triangle ma ọ bụ oblique mgbanaka njem usoro.

(2) N'agbanyeghị ụdị usoro njem a na-anabata, igwe weld ekwesịghị ịdị ukwuu mgbe ọ bụla ọ gafere n'ọdọ mmiri a wụrụ awụ.

Dị nwayọọ ígwè electrodes adabara n'elu ịgbado ọkụ bụAWS E6013, AWS E6010, AWS E6011, AWS E7018

Ọgụgụ 5. Tianqiao ịgbado ọkụ kwụ ọtọ

Ọgụgụ 5. Tianqiao ịgbado ọkụ kwụ ọtọ

Mgbado ọkụ kwụ ọtọ

Njirimara ịgbado ọkụ nke ịgbado ọkụ kwụ ọtọ:

1. Igwe a wụrụ awụ na-adaba n'ụzọ dị mfe n'ihi ịdị arọ nke ya, na-ebute ntụpọ ndị dị n'akụkụ elu, na bead weld nke nwere anya mmiri ma ọ bụ ntụpọ penetration ezughị ezu na akụkụ ala.

2. Igwe a wụrụ awụ na slag dị mfe ikewapụ, ntakịrị ka ịgbado ọkụ kwụ ọtọ.

Isi ihe nke ịgbado ọkụ kwụ ọtọ:

1. Butt nkwonkwo kehoraizin ịgbado ọkụ grooves bụ n'ozuzu V-ekara ma ọ bụ K ekara, butt nkwonkwo na a efere ọkpụrụkpụ nke 3 ~ 4mm nwere ike welded na abụọ na ụdị m grooves.

2. Jiri obere mkpara ịgbado ọkụ na dayameta, nke ugbu a ịgbado ọkụ dị obere karịa ewepụghị ịgbado ọkụ, obere arc ọrụ, nwere ike mma ịchịkwa eruba nke gbazere metal.

3. Mgbe ị na-agbado nnukwu efere, na mgbakwunye na weld ala, ọ bụ ihe amamihe dị na ya iji multi-layer na multi-pass welding.

4. Maka ịgbado ọkụ multi-layer na multi-pass, a ga-akwụ ụgwọ nlebara anya pụrụ iche iji chịkwaa ebe dị anya n'etiti weld passes.Maka ịgbado ọkụ nke ọ bụla, malite ịgbado ọkụ na 1/3 nke weld gara aga iji gbochie enweghị isi.

5. Dị ka ọnọdụ kpọmkwem, nọgide na-enwe kwesịrị ekwesị ịgbado ọkụ mkpara n'akuku, na ịgbado ọkụ ọsọ kwesịrị ubé blocky na edo.

6. Jiri usoro mbupu ziri ezi.

(1) N'ihi na Ụdị I butt kehoraizin ịgbado ọkụ, ọ ka mma iji a reciprocating linear warara ụzọ maka n'ihu ịgbado ọkụ onuete;Ekwesịrị iji eriri okirikiri kwụ ọtọ ma ọ bụ obere oblique mee ihe maka akụkụ ndị buru ibu, na ibe kwụ ọtọ n'akụkụ azụ, enwere ike ịgbado ọkụ ugbu a nke ọma.

(2) Jiri mgbado ọkụ kwụ ọtọ ọzọ.Mgbe ọdịiche ahụ dị ntakịrị, ịgbado ọkụ nke ala nwere ike iji eriri kwụ ọtọ;mgbe oghere ahụ buru ibu, oyi akwa nke ala na-anakwere ibe ahịrị ahịrị na-atụgharị;mgbe ndị ọzọ n'ígwé bụ multi-layer ịgbado ọkụ, nwere mmasị warara nwere ike iji.Ekwesịrị iji mbufe ahịrị kwụ ọtọ maka njem okirikiri nke ibe na ịgbado ọkụ multi-layer na ọtụtụ ngafe.

Dị nwayọọ ígwè electrodes adabara kehoraizin ịgbado ọkụ bụAWS E6013, AWS E6010, AWS E6011, AWS E7018

Oge nzipu: Jul-21-2021