Isi iyi ike nke brazing nwere ike ịbụ okpomọkụ mmeghachi omume kemịkal ma ọ bụ ike okpomọkụ na-apụtaghị ìhè.Ọ na-eji ígwè nwere ebe mgbaze dị ala karịa nke ihe a ga-agbado dị ka ihe na-ere.Mgbe ikpo ọkụ gasịrị, ihe na-agbaze na-agbaze, na capillary edinam na-akpali onye na-ere ahịa n'ime oghere dị n'etiti ebe kọntaktị nke njikọ ahụ iji mee ka mmiri dị n'elu ígwè ahụ ka a na-agbakọta ka mmiri mmiri na akụkụ siri ike kewapụ.Mgbakwụnye n'etiti usoro iji mepụta nkwonkwo brazed.Ya mere, brazing bụ usoro ịgbado ọkụ siri ike na nke mmiri mmiri.

1. Njirimara na ngwa nke brazing

Brazing na-eji alloy nwere ebe mgbaze dị ala karịa nke metal ala dị ka ihe na-ere ya.Mgbe a na-ekpo ọkụ, ihe na-agbaze na-agbaze ma na-ejupụta ma na-anọgide na nkwonkwo nkwonkwo site na wetting na capillary edinam, mgbe metal isi bụ na a siri ike ọnọdụ, na-adabere na mmiri mmiri solder na siri ike isi Interdiffusion n'etiti ihe na-etolite brazed nkwonkwo.Brazing nwere obere mmetụta na anụ ahụ na kemịkalụ Njirimara nke isi metal, obere ịgbado ọkụ nrụgide na deformation, nwere ike weld dissimilar ọla na nnukwu iche na Njirimara, nwere ike mezue otutu welds n'otu oge ahụ, ọdịdị nke nkwonkwo mara mma na edozi. akụrụngwa dị mfe, na ntinye ego mmepụta dị ntakịrị.Otú ọ dị, nkwonkwo brazed nwere ike dị ala na nkwụsị ọkụ na-adịghị mma.

Ngwa: Ihe eji egbutu Carbide, olulu mmiri, okpokolo agba igwe, ndị na-ekpo ọkụ, conduits na arịa dị iche iche, wdg;n'imepụta ngwa ngwa waveguides, ọkpọkọ elektrọn na ngwaọrụ oghere elektrọn, brazing bụ naanị ụzọ njikọ enwere ike.

2.metal brazing na flux

Brazing filler metal bụ ihe ndochi nke na-etolite isi brazing, na ịdị mma nke isi brazing na-adabere na ndochi brazing ruo n'ókè dị ukwuu.Igwe nkpuchi ahụ kwesịrị inwe ebe mgbaze kwesịrị ekwesị, ezigbo wettability na ikike nkedo, nwere ike gbasaa ya na metal ntọala, ma nwee ụfọdụ ihe eji arụ ọrụ na ihe anụ ahụ na nke kemịkal iji mezuo ihe ndị chọrọ ịrụ ọrụ nke nkwonkwo.Dị ka ebe mgbaze dị iche iche nke brazing filler metal si dị, enwere ike kewaa brazing ụzọ abụọ: brazing dị nro na brazing siri ike.

(1) brazing dị nro.A na-akpọ brazing na ebe mgbaze dị n'okpuru 450 Celsius C brazing dị nro, na metal brazing filler a na-ejikarị bụ tin lead brazing, nke nwere ezigbo wettability na eletriki ma na-ejikwa ya na ngwaahịa eletrọnịkị, ngwa moto na akụkụ akpaaka.Ike nke nkwonkwo brazed n'ozuzu 60 ~ 140MPa.

(2) Ịgba ọsọ.A na-akpọ brazing nke nwere ebe mgbaze dị elu karịa 450 Celsius C brazing, na ihe brazing a na-ahụkarị bụ ihe brass na ọla ọcha.Njikọ ya na ọlaọcha isi ihe mkpuchi ọla nwere ike dị elu, eletriki eletrik na nguzogide corrosion, ebe mgbaze nke metal filler dị ala, na usoro ahụ dị mma, mana ọnụahịa nke ihe mkpuchi dị elu, a na-ejikarị ya eme ihe maka ịgbado ọkụ. akụkụ na elu chọrọ.A na-ejikarị brazing eme ihe maka ígwè na ọla kọpa alloy workpieces nwere nnukwu ike, yana maka ngwa brazing.Ike nkwonkwo brazed nke 200 ~ 490MPa,

Rịba ama: Elu kọntaktị nke ihe mgbakwasị ụkwụ kwesịrị ịdị ọcha nke ukwuu, ya mere, a ga-eji ntụgharị ahụ mee ihe.Ọrụ nke flux bụ iji wepụ oxide na mmanụ na-adịghị ọcha n'elu ala nke isi na ígwè na-ekpuchi ihe, na-echebe elu kọntaktị nke metal filler na isi metal sitere na oxidation, ma mee ka wettability na capillary fluidity nke ihe mkpuchi. igwe.Ebe mgbaze nke mmiri na-agbaze kwesịrị ịdị ala karịa nke igwe na-ejuputa, na nrụrụ nke flux fọdụrụnụ na metal ala na nkwonkwo kwesịrị ịdị ntakịrị.Ọkpụkpụ brazing a na-ahụkarị bụ rosin ma ọ bụ zinc chloride ngwọta, na mgbawa brazing na-emekarị bụ ngwakọta nke borax, boric acid na alkaline fluoride.

Dabere na isi mmalite okpomọkụ dị iche iche ma ọ bụ ụzọ kpo oku, enwere ike kewaa brazing n'ime:ire ọkụ, brazing induction, ọkụ brazing, itinye brazing, mgbochi mgbochi na ihe ndị ọzọ.N'ihi na okpomọkụ na-ekpo ọkụ dị ntakịrị n'oge brazing, ọ na-enwechaghị mmetụta na arụmọrụ nke ihe arụ ọrụ, na nrụrụ nrụgide nke weldment dịkwa obere.Otú ọ dị, ike nke nkwonkwo brazed na-adịkarị ala, na nkwụsị okpomọkụ adịghị mma.

Ụzọ kpo oku brazing:Enwere ike iji ihe fọrọ nke nta ka ọ bụrụ ebe niile na-ekpo ọkụ dị ka isi iyi ọkụ brazing, yana dịka brazing a ka a na-ekewa.

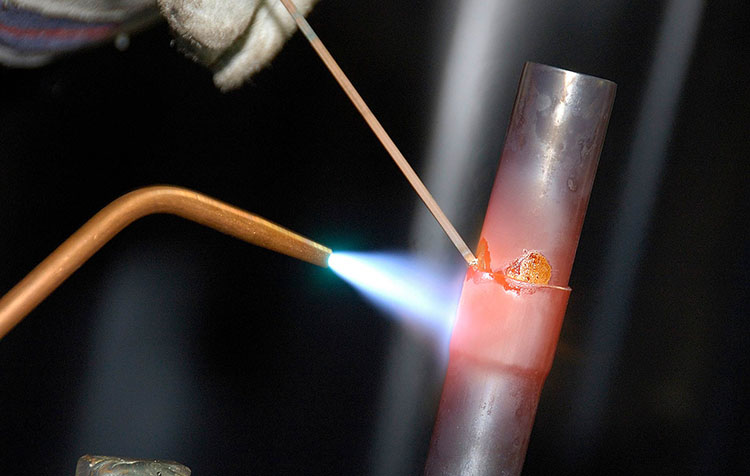

Ịgba ọkụ:kpo oku na ọkụ gas, eji maka carbon ígwè, igwe anaghị agba nchara, carbide, nkedo ígwè, ọla kọpa na ọla kọpa alloys, aluminum na aluminum alloy brazing.

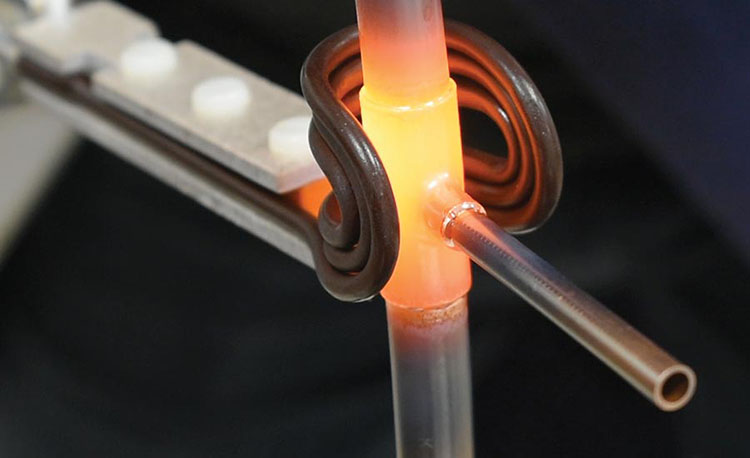

Induction brazing:Ojiji nke ndọta ndọta ọzọ na-eme ka ọ bụrụ ihe a na-eme ugbu a na akụkụ nke ịgbado ọkụ na-eguzogide okpomọkụ, maka ọdịdị nke ịgbado ọkụ, ọkachasị brazing nke ogwe ọkpọkọ.

Ntụnye brazing:akụkụ ịgbado ọkụ bụ akụkụ ma ọ bụ kpam kpam na-emikpu na ngwakọta nnu gbazere ma ọ bụ solder gbazee, na-adabere na okpomọkụ nke mgbasa ozi mmiri ndị a iji nweta usoro brazing, nke a na-eji ngwa ngwa kpo oku, okpomọkụ edo, obere nrụrụ nke akụkụ ịgbado ọkụ.

Ọkụ brazing:A na-eji ọkụ na-eguzogide welds na-ekpo ọkụ, nke nwere ike ichekwa welds site na ikpochapụ ma ọ bụ iji mbelata ma ọ bụ inert gas.

Tụkwasị na nke ahụ, e nwere ihe na-eme ka ígwè brazing, mgbochi mgbochi, mgbasa brazing, brazing infrared, mmeghachi omume brazing, electron beam brazing, laser brazing, wdg.

Enwere ike iji brazing weld carbon steel, igwe anaghị agba nchara, superalloy, aluminom, ọla kọpa na ihe igwe ndị ọzọ, ma nwee ike jikọọ ọla ndị yiri ya, ọla na ndị na-abụghị ọla.Kwesịrị ekwesị maka nkwonkwo ịgbado ọkụ na obere ibu ma ọ bụ na-arụ ọrụ na ụlọ okpomọkụ, karịsịa maka nkenke, micro na mgbagwoju multi-brazed welds.

Oge nzipu: Jul-06-2023