Mgbado ọkụ nke metal Arc Shielded (nke akpọrọ SMAW).Ụkpụrụ bụ: a na-emepụta arc n'etiti electrode mkpuchi mkpuchi na metal base, na usoro ịgbado ọkụ na-eji ọkụ arc na-agbaze electrode na metal ala.A na-eji mmiri ịgbado ọkụ kpuchie elu elu nke electrode ma gbazee mgbe ọ na-ekpo ọkụ, nke nwere ọrụ nke ime ka arc ahụ guzosie ike, na-emepụta slag, deoxidizing, na nchacha.N'ihi na ọ na-achọ ngwá ọrụ dị mfe na ịrụ ọrụ na-agbanwe agbanwe, ọ nwere ike ịdị mfe welded na welds nke e guzobere site na ọnọdụ dị iche iche na nkwonkwo dị iche iche na mbara igwe.Ya mere, a ka na-eji ya eme ihe ugbu a.

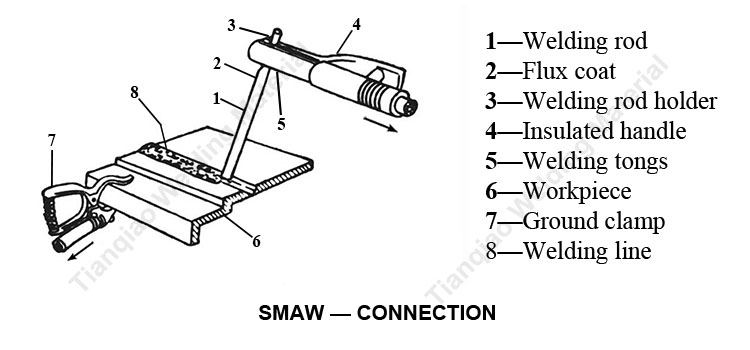

Onyonyo 1: Mgbado nke Metal Arc Welding-njikọ

E gosipụtara ịgbado ọkụ n'aka na foto a:

Tupu ịgbado ọkụ, jikọọ welded workpiece na welding tongs na okporo osisi abụọ nke eletriki ịgbado ọkụ igwe na mwekota na ịgbado ọkụ mkpanaka na ịgbado ọkụ.N'oge ịgbado ọkụ, mkpara ịgbado ọkụ na workpiece bụ ozugbo kọntaktị, na-akpụ a obere sekit, na mgbe ahụ, ha na-ekewapụ site a ụfọdụ anya (banyere 2-4mm), na arc na-enwu.

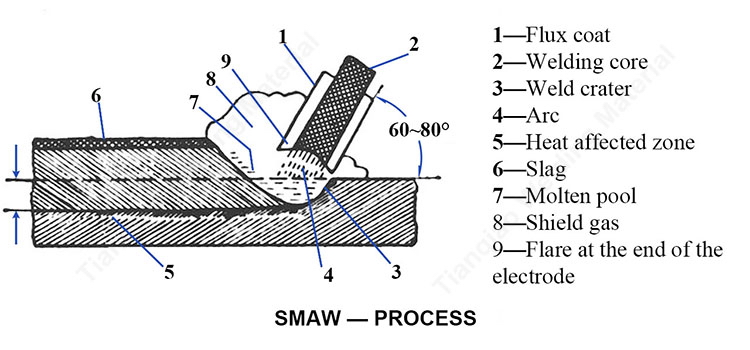

Onyonyo 2: Usoro ịgbado ọkụ metal Arc na-echebe

Ihe arụ ọrụ n'okpuru arc na-agbaze ozugbo ka ọ bụrụ ọdọ mmiri a wụrụ awụ nke ọkara oval.Mgbe mkpuchi electrode gbazere, akụkụ ya na-aghọ gas nke na-agba gburugburu arc iji kewapụ ya na ikuku, si otú ahụ na-echebe metal mmiri mmiri site na oxygen na nitrogen;akụkụ ya na-aghọ slag a wụrụ awụ, ma ọ bụ fesa n'ime ọdọ mmiri a wụrụ awụ naanị, ma ọ bụ gbazere ya na isi A na-efesa ụmụ irighiri mmiri a wụrụ awụ nke ọla mmiri n'ọdọ mmiri ahụ gbazere ọnụ.

N'ime arc na ọdọ mmiri a wụrụ awụ, mmiri mmiri metal, slag na arc gas ga-enwe ụfọdụ mgbanwe anụ ahụ na nke kemịkal na ibe ha, dị ka mgbasa nke gas n'ime mmiri mmiri na mmeghachi omume oxidation-mbelata.Gas na slag dị na ọdọ mmiri a wụrụ awụ na-ese n'elu n'ihi ịdị arọ ya.Mgbe e wepụrụ arc ahụ, okpomọkụ na-adaba na ígwè na slag ga-esiwanye ike n'otu n'otu.N'ụzọ dị otú a, a na-ejikọta akụkụ abụọ nke ígwè ahụ site na ígwè weld gbazere na crystallized.N'ihi na mbelata nke slag dị iche na nke ígwè ahụ, ọ ga-adaba na shea slag na oke ígwè, na slag shell nwere ike ịdapụ na-akpaghị aka, ma ọ bụ daa mgbe a kụsịrị ya, na ígwè weld nke nwere akpịrịkpa azụ. nwere ike ikpughe.

Isi akụrụngwa nke akwụkwọ ịgbado ọkụ arc bụ igwe ịgbado ọkụ eletrik.Igwe ịgbado ọkụ eletrik bụ isi iyi nke na-emepụta arc ịgbado ọkụ, yana ụdị AC na DC abụọ dị.Ka ọ dị ugbu a, e nwere ọtụtụ ụdị igwe ịgbado ọkụ eletrik arụpụtara na China, nke enwere ike kewaa ya igwe igwe AC na igwe ịgbado ọkụ DC dịka usoro ha siri dị.

Enwere ụzọ njikọ abụọ dị iche iche maka igwe ịgbado ọkụ DC.Mgbe ejikọrọ na electrode na-adịghị mma na workpiece na-ejikọta na electrode dị mma, ọ bụ usoro njikọ dị mma;nke dị iche bụ ụzọ njikọ azụ.N'ozuzu, mgbe ịgbado ọkụ na alkaline ala-hydrogen electrode (dị kaE7018, E7016), iji mee ka arc ahụ na-ere ọkụ nke ọma, a kwadoro iji usoro njikọ ntụgharị DC;mgbe ị na-eji electrode acid (dịkaE6013, J422) iji weld nnukwu efere ígwè, a na-eji usoro njikọ na-aga n'ihu, n'ihi na akụkụ anode Ọnọdụ okpomọkụ dị elu karịa akụkụ cathode, na usoro njikọ na-aga n'ihu nwere ike nweta nnukwu ntinye ntinye;mgbe ị na-agbado efere ígwè dị mkpa na ọla ndị na-abụghị ígwè, a na-eji usoro njikọ azụ.Mgbe ịgbado ọkụ na alternating current, ebe ọ bụ na polarity na-agbanwe ọzọ, ọ dịghị mkpa ịhọrọ polarity njikọ.

Ihe ịgbado ọkụ maka ịgbado ọkụ n'aka bụ mkpanaka ịgbado ọkụ eletrik, nke nwere isi nchara na mkpuchi n'èzí nchara nchara (Ọkwa hụ.Ihe mejupụtara electrode ịgbado ọkụ).

Isi ịgbado ọkụ

Ọrụ nke isi ígwè (welding core) bụ isi na-eduzi ọkụ eletrik ma na-emepụta ígwè a na-edebe ihe na ihe ụfọdụ na njedebe nke electrode.Enwere ike iji ígwè dị iche iche mee isi ịgbado ọkụ.Ngwakọta nke isi ịgbado ọkụ na-emetụta kpọmkwem ihe mejupụtara na arụmọrụ nke ọla edobere.Ya mere, a chọrọ isi ịgbado ọkụ iji belata ọdịnaya nke ihe ndị na-emerụ ahụ.Na mgbakwunye na ịmachi S na P, ụfọdụ mkpanaka ịgbado ọkụ chọrọ ka isi ịgbado ọkụ jikwaa As, Sb, Sn na ihe ndị ọzọ.

Ọgụgụ 3: Tianqiao welding electrode E6013

Uwe mkpuchi

A pụkwara ịkpọ mkpuchi electrode agba.Ebumnuche bụ isi nke mkpuchi ya na isi bụ iji mee ka ọrụ ịgbado ọkụ na-arụ ọrụ na iji hụ na ígwè a na-echekwara nwere ụfọdụ ihe mejupụtara na arụmọrụ.Enwere ike ịgwakọta ihe mkpuchi elektrọn na ọtụtụ narị ntụ ntụ akụrụngwa dị ka oxides, carbonates, silicates, organics, fluorides, ferroalloys na ngwaahịa kemịkalụ dabere na usoro ụfọdụ.Enwere ike kewaa akụrụngwa dị iche iche n'ụdị ndị a dịka ọrụ ha na mkpuchi electrode si dị:

1. Stabilizer na-eme ka electrode dị mfe ịmalite arc ma nwee ike ịnọgide na-agba ọkụ ọkụ n'oge usoro ịgbado ọkụ.Ihe ọ bụla dị mfe ionize nwere ike ime ka arc ahụ guzosie ike.N'ozuzu, a na-eji ogige alkali ọla na alkaline ụwa ọla, dị ka potassium carbonate, sodium carbonate, marble, wdg, na-eji.

2. Onye na-emepụta Slag nwere ike ịmepụta slag a wụrụ awụ na ụfọdụ ihe anụ ahụ na nke kemịkal n'oge ịgbado ọkụ, na-ekpuchi elu nke ígwè a wụrụ awụ, na-echebe ọdọ mmiri ịgbado ọkụ na imeziwanye ọdịdị nke weld.

3. Deoxidizer site na mmeghachi omume kemịkalụ metallurgical na usoro ịgbado ọkụ iji belata ọdịnaya oxygen na weld metal ma melite akụrụngwa akụrụngwa nke weld.Ndị na-emepụta ihe na-emepụta ihe bụ ferromanganese, ferrosilicon, na ferro-titanium.

4. Onye na-emepụta ihe na-emepụta gas nwere ike ikewapụ na ịtọhapụ gas n'okpuru omume nke arc dị elu okpomọkụ iji chebe arc na ọdọ mmiri a wụrụ awụ ma gbochie ntinye nke oxygen na nitrogen na ikuku gbara ya gburugburu.

5. Alloying agent A na-eji ya kwụọ ụgwọ maka ọkụ nke ihe ndị na-ekpo ọkụ na mgbanwe nke ihe ndị na-emepụta ihe na-eme ka ọkpụkpụ na-eme ka ọ bụrụ ihe na-eme ka ọkpụkpụ na-eme ka ọ bụrụ ihe na-eme ka ọ bụrụ ihe na-eme ka ọkpụkpụ na-eme ka ọ bụrụ ihe na-emepụta ihe na-emepụta ihe na-arụ ọrụ nke kemịkalụ dị mkpa.

6. Plasticizing Lubricant Na-abawanye plasticity, slippage na fluidity of the cover powder in the welding stick pressing process to improve the press quality of the welding stick and reduce the eccentricity.

7. Adhesives Mee ka ntụ ntụ mkpuchi nwere ụfọdụ viscosity n'oge usoro mkpuchi mkpakọ, nwere ike jikọta ya na isi ịgbado ọkụ, ma mee ka mkpuchi mkpara ịgbado ọkụ nwere ụfọdụ ike mgbe ihichachara.

Oge nzipu: Jul-27-2021