Igwe ịgbado ọkụ bụ mkpanaka ígwè nke na-agbaze ma jupụta na nkwonkwo nke ọrụ ịgbado ọkụ n'oge ịgbado ọkụ gas ma ọ bụ ịgbado ọkụ eletrik.Ngwongwo nke electrode na-abụkarị otu ihe nke ihe eji arụ ọrụ.

Ebe a, anyị na-abịa ịghọta otú na ịgbado ọkụ electrode mejupụtara:

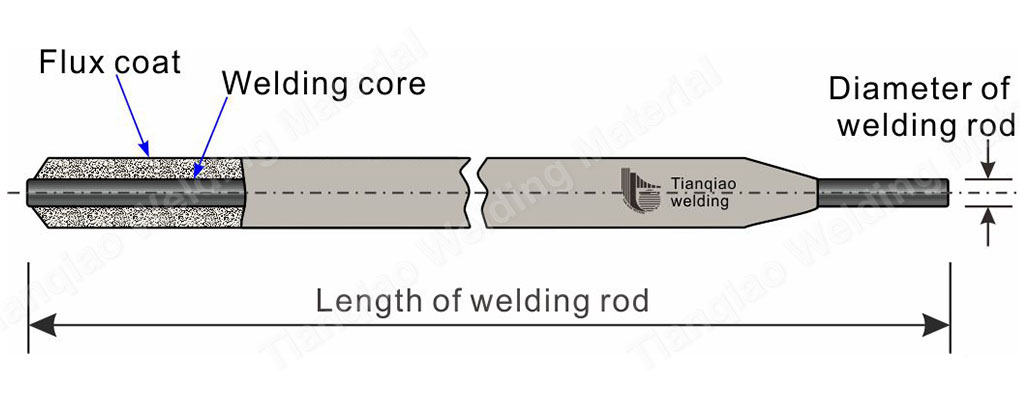

Ọgụgụ 1 Ọdịdị nke Tianqiao welding electrode

Igwe ịgbado ọkụ bụ electrode na-agbaze nke ejiri mkpuchi maka ịgbado ọkụ nke mkpanaka ịgbado ọkụ.Ihe mejupụtara ya bụ mkpuchi na isi ịgbado ọkụ.

A na-akpọ isi ígwè nke mkpuchi mkpuchi na mkpara ịgbado ọkụisi ịgbado ọkụ.Isi ịgbado ọkụ n'ozuzu bụ waya ígwè nwere ogologo ogologo na dayameta.

Ọgụgụ 2 Isi nke Tianqiao welding electrode

Ọrụ abụọ nke isi

1. Na-eduzi ịgbado ọkụ ugbu a na ịmepụta arc iji gbanwee ike eletrik n'ime okpomọkụ.

2. Isi ịgbado ọkụ n'onwe ya na-agbaze dị ka igwe na-ejuputa ma na-ejikọta ya na mmiri mmiri isi metal na-etolite weld.Mgbe ị na-eji eletrọd na-agbado, igwe bụ isi na-enwe otu akụkụ nke metal weld dum.Ya mere, ihe mejupụtara kemịkalụ nke isi weld na-emetụta àgwà nke weld ozugbo.Ya mere, waya ígwè eji dị ka isi nke electrode nwere akara ya na ihe mejupụtara ya iche iche.

Ihe mkpuchi electrodena-ezo aka na mkpuchi mkpuchi etinyere n'elu nke isi ịgbado ọkụ.A na-emebi ihe mkpuchi ahụ ma gbazee na usoro ịgbado ọkụ iji mepụta gas na slag, nke na-ekere òkè na nchedo ígwè ọrụ, ọgwụgwọ metallurgical, na imeziwanye arụmọrụ usoro.

Ọgụgụ 3 Mkpuchi nke Tianqiao welding electrode

Ngwakọta nke mkpuchi na-agụnye: mineral (dị ka marble, fluorspar, wdg), ferroalloys na metal powders (dị ka ferromanganese, ferro-titanium, wdg), organic bekee (dị ka osisi ntụ ọka, cellulose, wdg). ngwaahịa kemịkalụ (dị ka titanium dioxide, iko mmiri, wdg).Ihe mkpuchi electrode bụ ihe dị mkpa n'ịchọpụta àgwà nke welds.

Isi ọrụ nke mkpuchi na usoro ịgbado ọkụ

1. Melite nkwụsi ike nke combustion arc:

Eletrọd na-enweghị mkpuchi adịghị mfe ịgbanye arc.Ọ bụrụgodị na agbanyere ya ọkụ, ọ pụghị ire ọkụ.

2. Chebe ọdọ mmiri weld:

N'oge usoro ịgbado ọkụ, oxygen, nitrogen na mmiri vapor nke ikuku na-abanye n'ime eriri weld, nke ga-enwe mmetụta dị njọ na eriri weld.Ọ bụghị nanị na e guzobere pores, kamakwa ibelata n'ibu Njirimara nke weld, na ọbụna ime ka cracks.Mgbe ihe mkpuchi electrode gbazere, a na-emepụta nnukwu gas na-ekpuchi arc na ọdọ mmiri a wụrụ awụ, nke ga-ebelata mmekọrịta dị n'etiti ígwè a wụrụ awụ na ikuku.Mgbe weld ahụ dị jụụ, mkpuchi agbaze agbaze na-etolite akwa slag, nke na-ekpuchi elu nke weld, na-echebe ígwè weld ma mee ka ọ dị jụụ nwayọọ nwayọọ, na-ebelata ohere nke porosity.

Atọ, iji hụ na weld bụ deoxidized na desulfurized na phosphorus adịghị

Ọ bụ ezie na a na-eme nchebe n'oge usoro ịgbado ọkụ, ọ ka bụ ihe a na-apụghị izere ezere na obere ikuku oxygen ga-abanye n'ọdọ mmiri ahụ a wụrụ awụ iji mee ka ígwè na ihe ndị na-emepụta ihe na-ekpo ọkụ na-ekpo ọkụ, na-ere ihe ndị na-emepụta ihe na-ekpo ọkụ, ma belata ịdị mma nke weld.Ya mere, ọ dị mkpa ịgbakwunye ihe na-ebelata (dị ka manganese, silicon, titanium, aluminom, wdg) na mkpuchi electrode iji belata oxides ndị na-abanye na ọdọ mmiri a wụrụ awụ.

4. Ihe mgbakwunye alloying maka weld:

N'ihi mmetụta dị elu nke okpomọkụ nke arc, a ga-ekpochapụ ihe ndị na-emepụta ihe nke metal weld na ọkụ, nke ga-ebelata ihe eji arụ ọrụ nke weld.Ya mere, ọ dị mkpa ịgbakwunye ihe ndị na-edozi ihe kwesịrị ekwesị na weld site na mkpuchi iji kwụọ ụgwọ ọkụ na-ere ọkụ nke ihe ndị na-emepụta ihe na iji hụ ma ọ bụ meziwanye ihe eji arụ ọrụ nke weld.Maka ịgbado ọkụ nke ụfọdụ alloy steels, ọ dịkwa mkpa ịbanye na alloy n'ime weld site na mkpuchi ahụ, nke mere na weld metal nwere ike ịbịaru nso n'ụdị metal nke isi metal, na ihe ndị na-arụ ọrụ nwere ike ijide ma ọ bụ ọbụna karịa. isi metal.

5. Melite nrụpụta ịgbado ọkụ ma belata spatter:

Ihe mkpuchi electrode nwere mmetụta nke ịba ụba droplet na ibelata spatter.Ebe mgbaze nke mkpuchi electrode dị ntakịrị ala karịa ebe ịgbado ọkụ nke isi.Otú ọ dị, n'ihi na isi ịgbado ọkụ dị n'etiti arc na okpomọkụ dị oke elu, isi ịgbado ọkụ na-agbaze na mbụ, mkpuchi ahụ na-agbazekwa obere oge.N'otu oge ahụ, ebe ọ bụ na mfu ígwè nke spatter na-akpata na-ebelata, ọnụọgụ ntinye ego na-abawanye, na mmepụta nke ịgbado ọkụ na-emekwa ka mma.

Oge nzipu: Jun-01-2021